A project started in 2018, which Idromeccanica Lucchini has developed in Georgia, has been in full swing for a few months now. The greenhouse plant covered by the intervention concerns the cultivation of hazelnuts for the confectionery industry.

High qualitative Standards

The hazelnuts, processed by the Georgian headquarters of Ferrero Company, by the will of the same Multinational, must be grown in the area where the finished good will be processed. This "local for local" philosophy, in fact, requires hazelnuts production and processing in a single site. The seedlings, supplied by the Italian company, are the same in all countries where Ferrero has a branch, in order to obtain a product with the same high quality standards in every part of the world.

The core peculiarities

The stone is a plant that begins producing after 3 - 4 years from its birth. The production of the fruit then proceeds for about 40 years. The particular climatic conditions in Georgia make it difficult for the plants to survive in the early stages of their growth and it was therefore necessary to design a greenhouse plant that would allow young stones to grow in shelter, and then be transplanted later in the orchards in the hills. The Georgian nursery is located in the town of Zugdidi, not far from the coast of the Black Sea, and is property of the company Agrigeorgia.

The Intervention

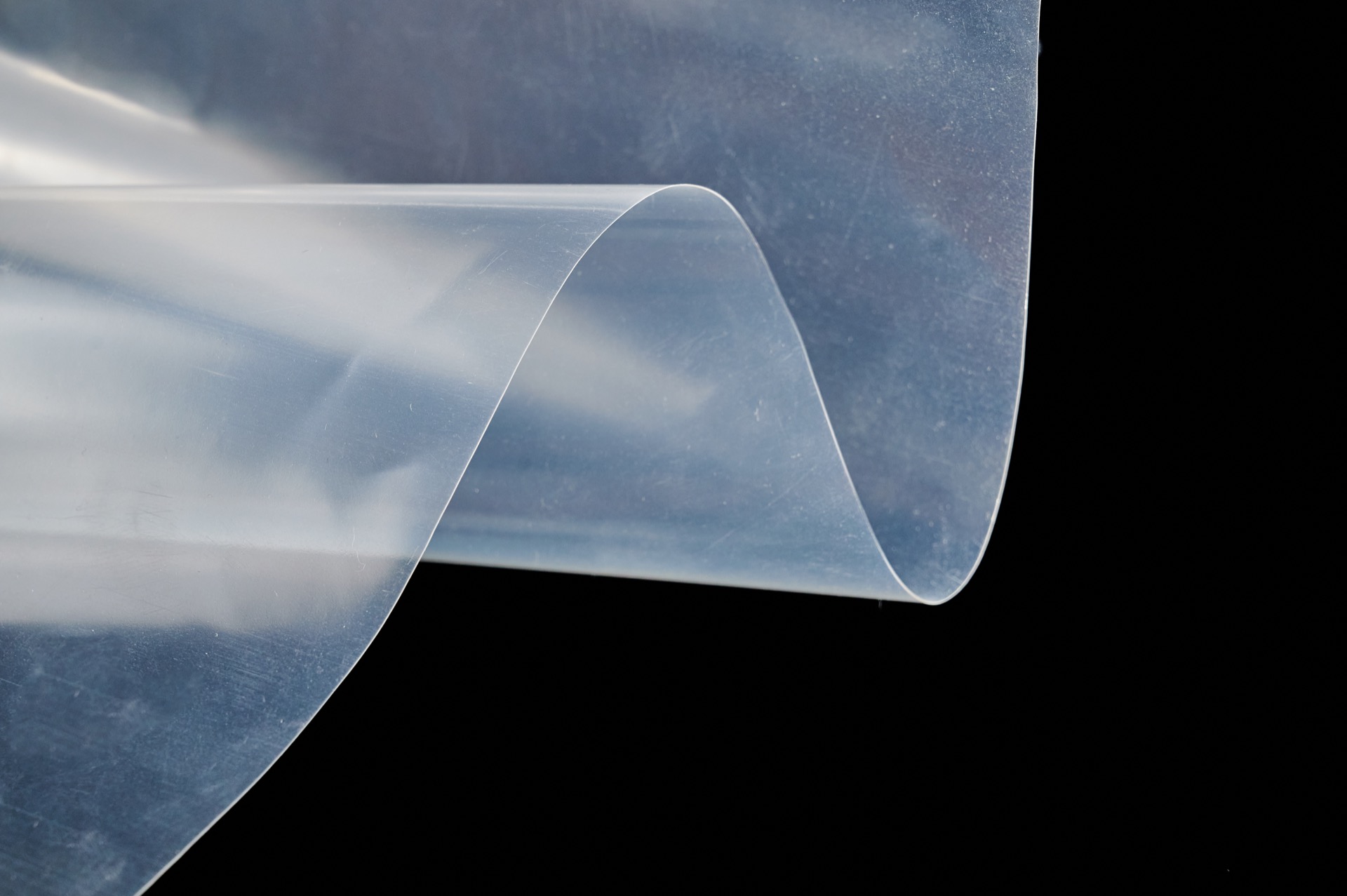

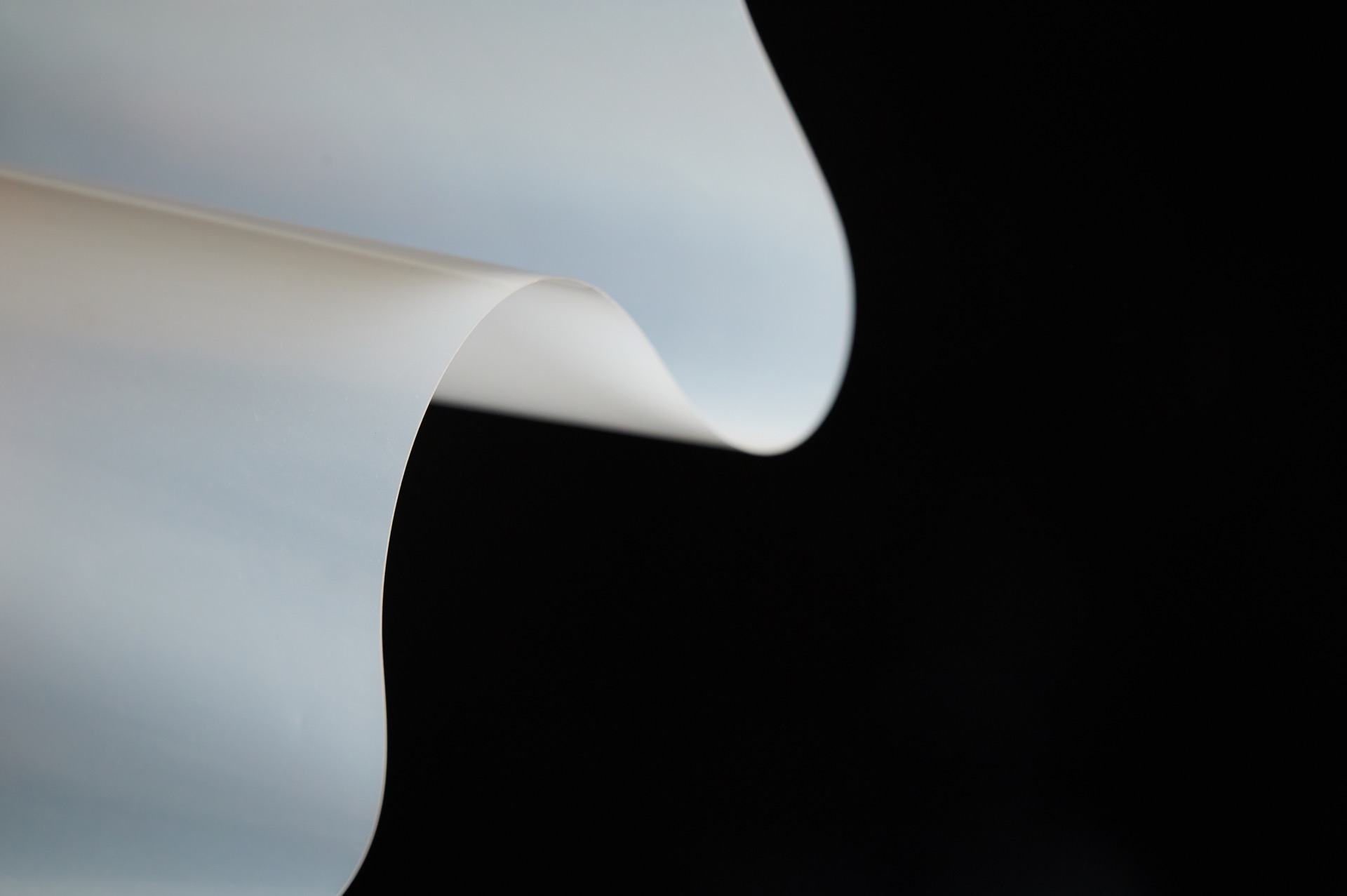

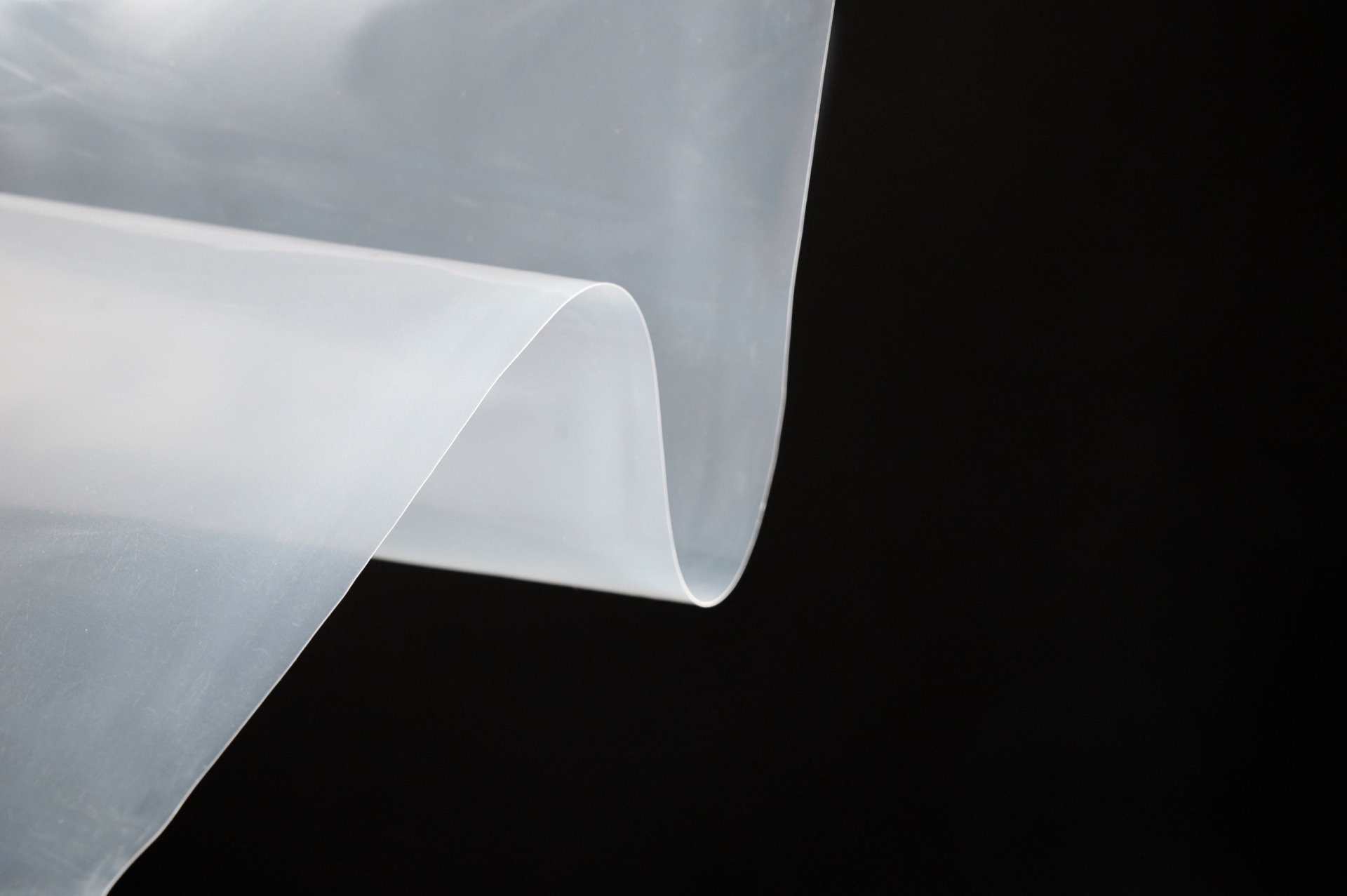

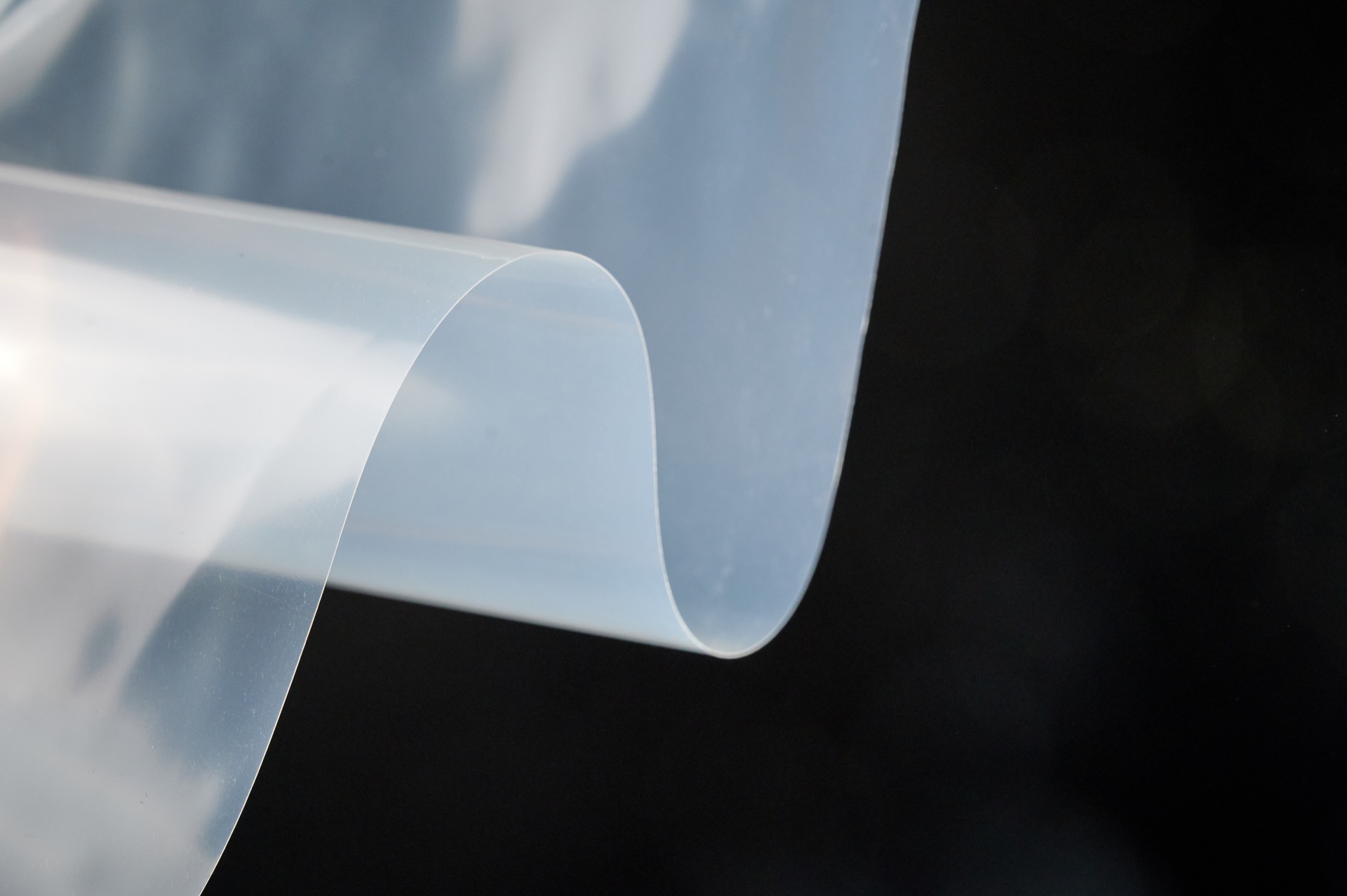

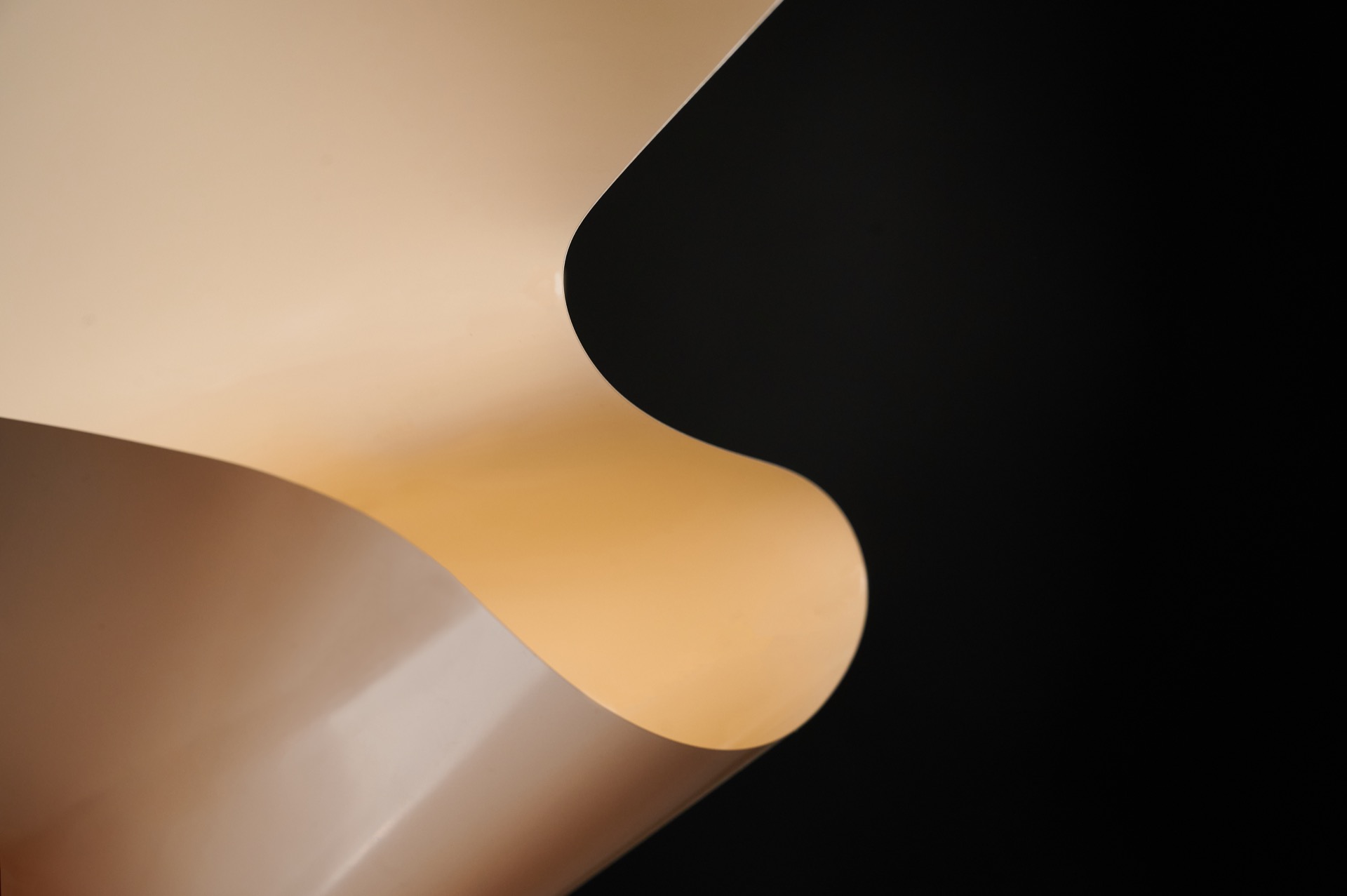

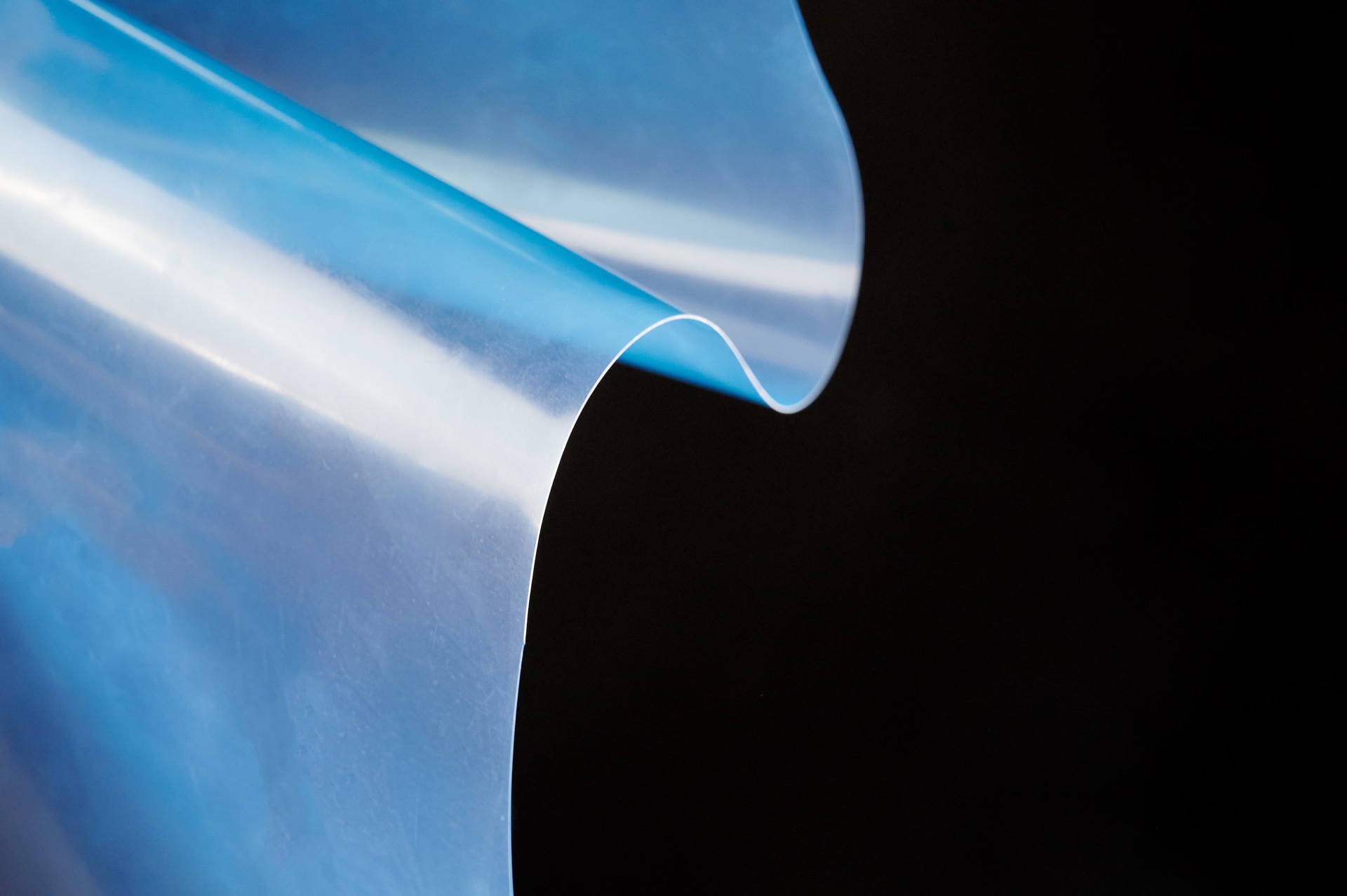

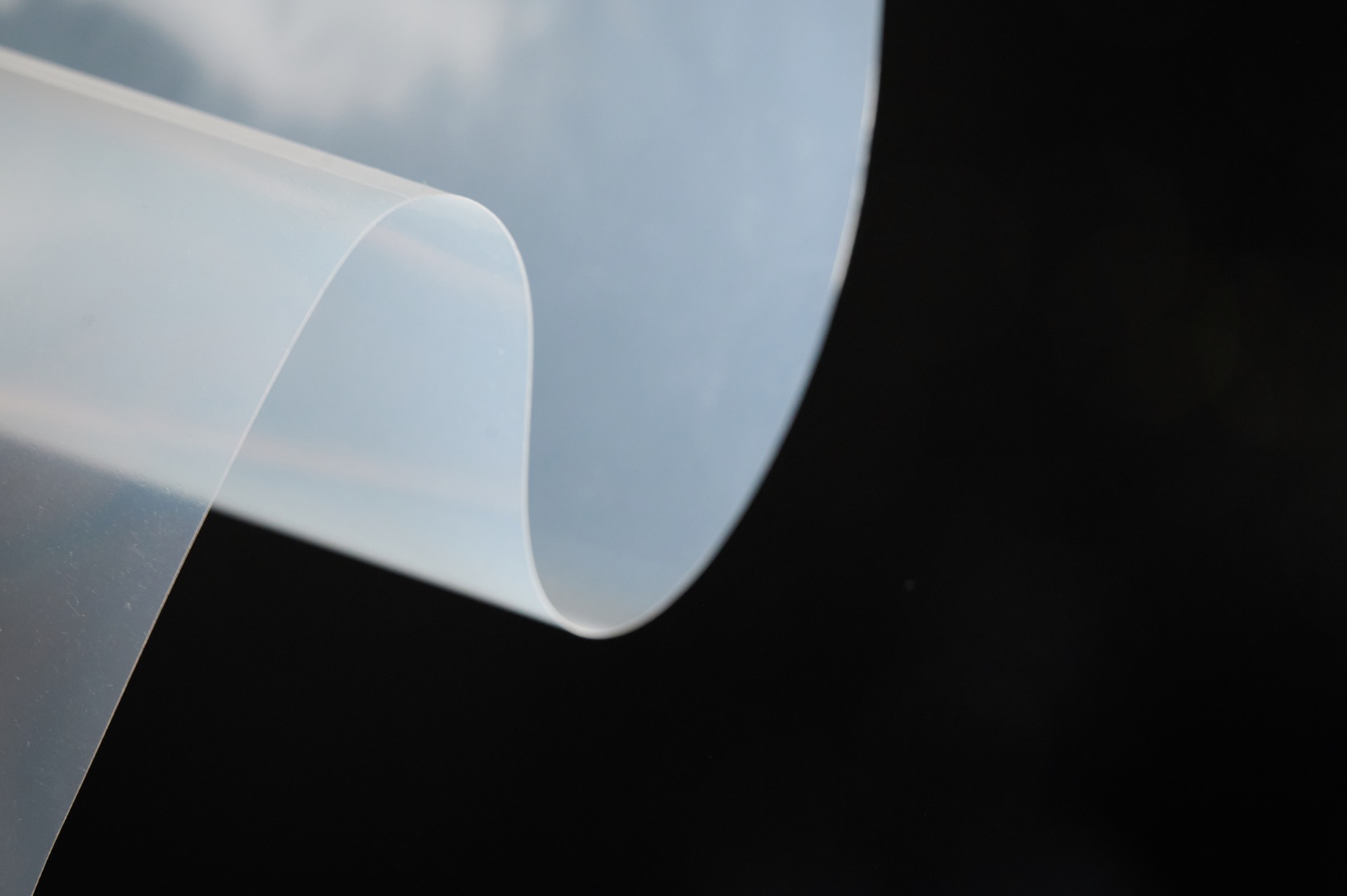

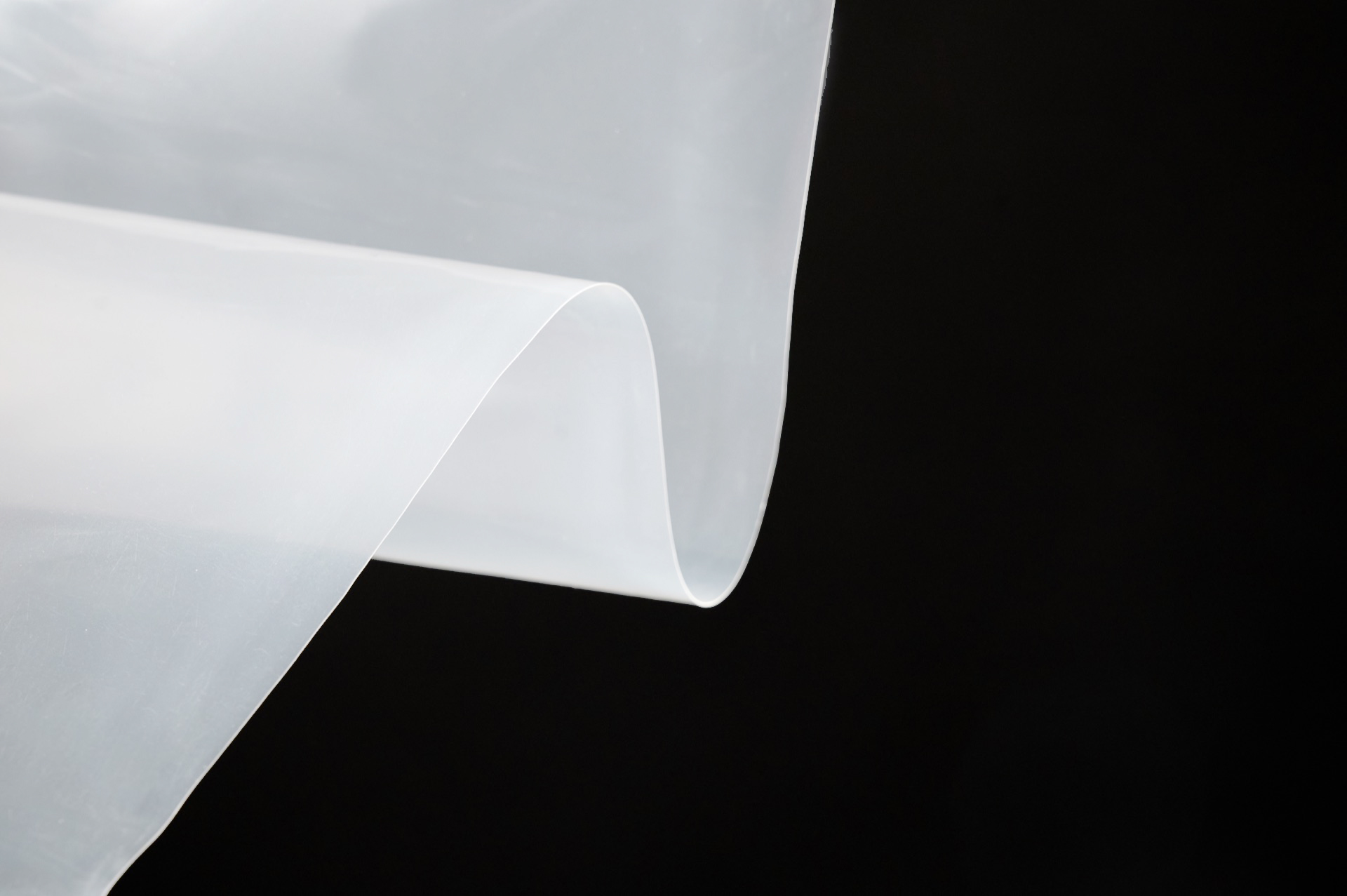

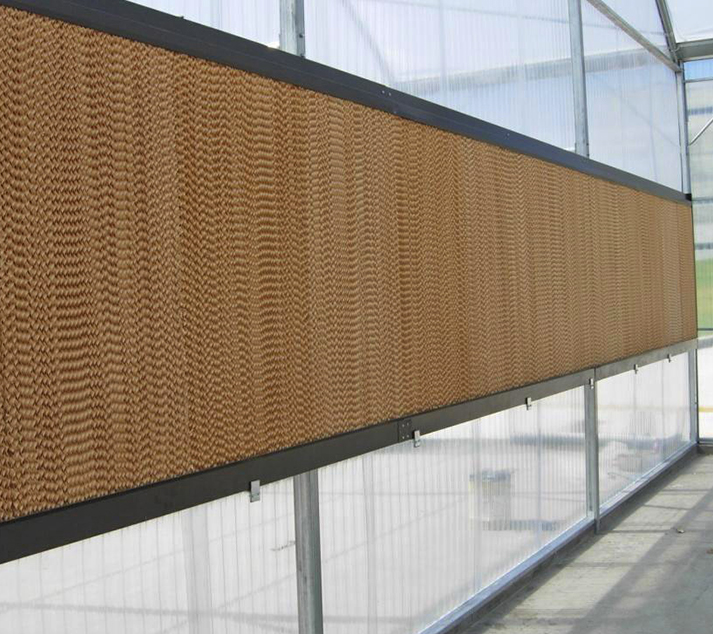

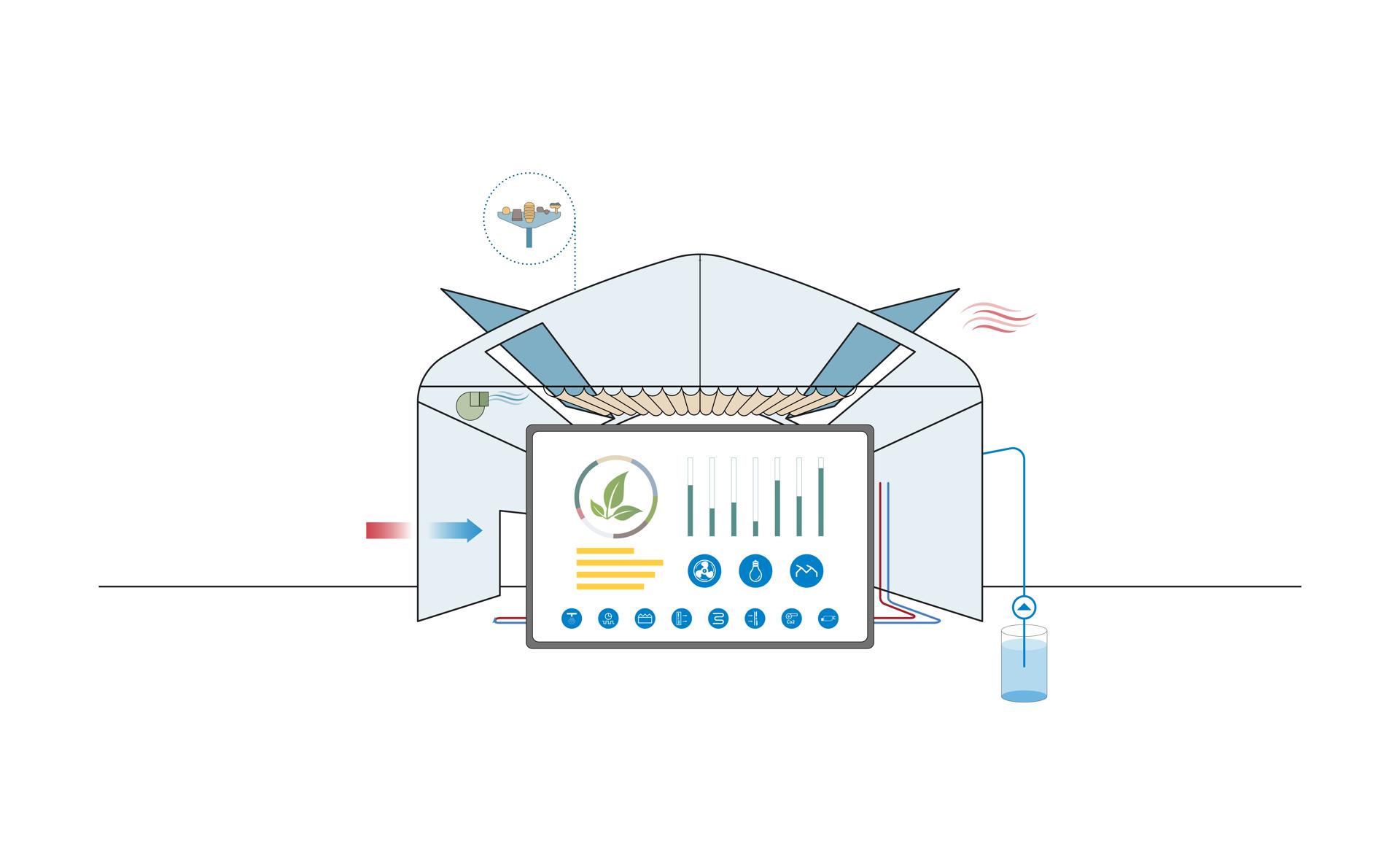

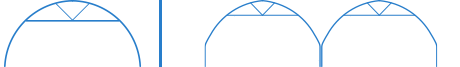

After some meetings with the Italian Management, Idromeccanica Lucchini has studied a pre-nursery structure for the growth of hazelnut seedlings. The idea was to use a modified and customized version of the Atlantic TS greenhouse, which was raised to achieve greater air volume with a more stable temperature inside the greenhouse. Given the extreme climatic conditions, it was in fact necessary to have an air volume that was less affected by the thermal variations of the territory. To the greenhouse has been applied a cover with a diffused light covering to avoid excessive insolation, also suitable to take advantage of the most of the scarce light in the colder seasons. Thanks to the properties of this covering, the light is diffused more uniform. The greenhouse has also been added a network coverage to limit the excess of solar radiation that allows the necessary light passage for the prosperity and growth of the core. As a first intervention, 18 greenhouses were built with a capacity of 5,000 stone plants per greenhouse. The total of 90,000 plants has a density of 18 plants per square metre.

Irrigation and areation

The growth of hazelnut seedlings in greenhouses is a challenge which presents several difficulties:

• The long permanence of the plants in greenhouse before being possible the transplanting in the orchard

• The need to obtain equal plants with the same potential

• The need to preserve seedlings from pathogens and external agents

• The limited space available for each plant

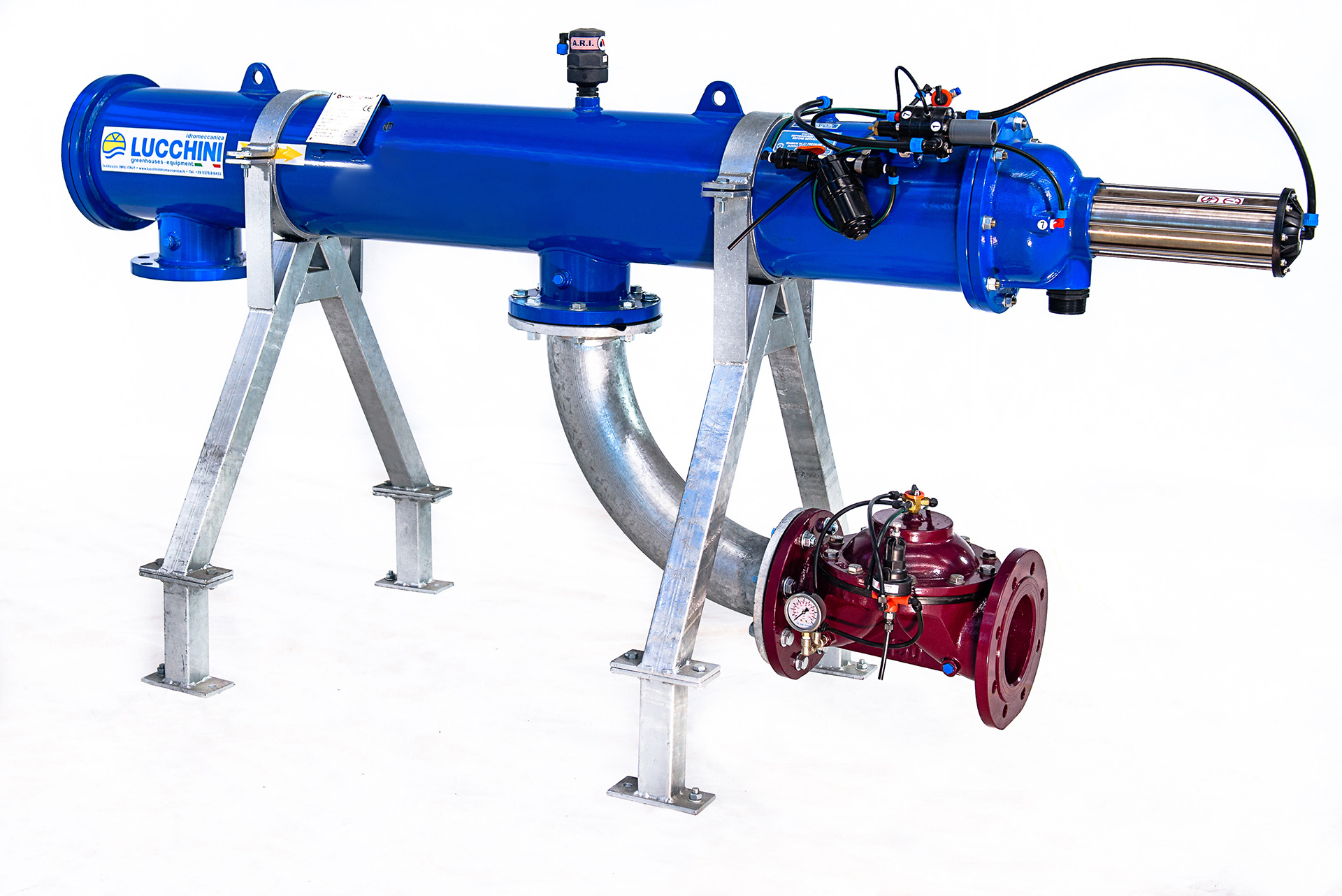

To solve all these problems the technicians and agronomists of Idromeccanica Lucchini have methodically arranged the plants in order to give them an adequate living space. Plants were placed in plastic bags equipped with a dripper per bag to bring water and nourishment. The stones are fed in a homogeneous way and with a calibrated and precise standard, through a duct that from the well reaches every single plant. To avoid the formation of fungus and to ensure maximum ventilation, the Atlantic TS greenhouses were supplied with side and front openings. In addition, in summer it is possible to open the greenhouses completely turning them into a kind of net house.

A project studied in every detail

Given the difficulty of the challenge, Idromeccanica Lucchini has taken care of the project both from the Mother Company and from its local division located in Georgia. Lucchini team, located on site for over three months, has also taken care of the construction of the greenhouse from the foundations to the water pump. Design, choice of materials, construction and logistics have been scrupulously curated by Idromeccanica Lucchini to be able to complete a complex intervention that is already bearing the first fruits.

The result of the project

Now in the third season, the greenhouse has obtained very positive references, so much so that we are already thinking of enlargements. A similar installation has already been put in place in Kyrgyzstan and further interventions based on this project are also being studied in Ukraina.