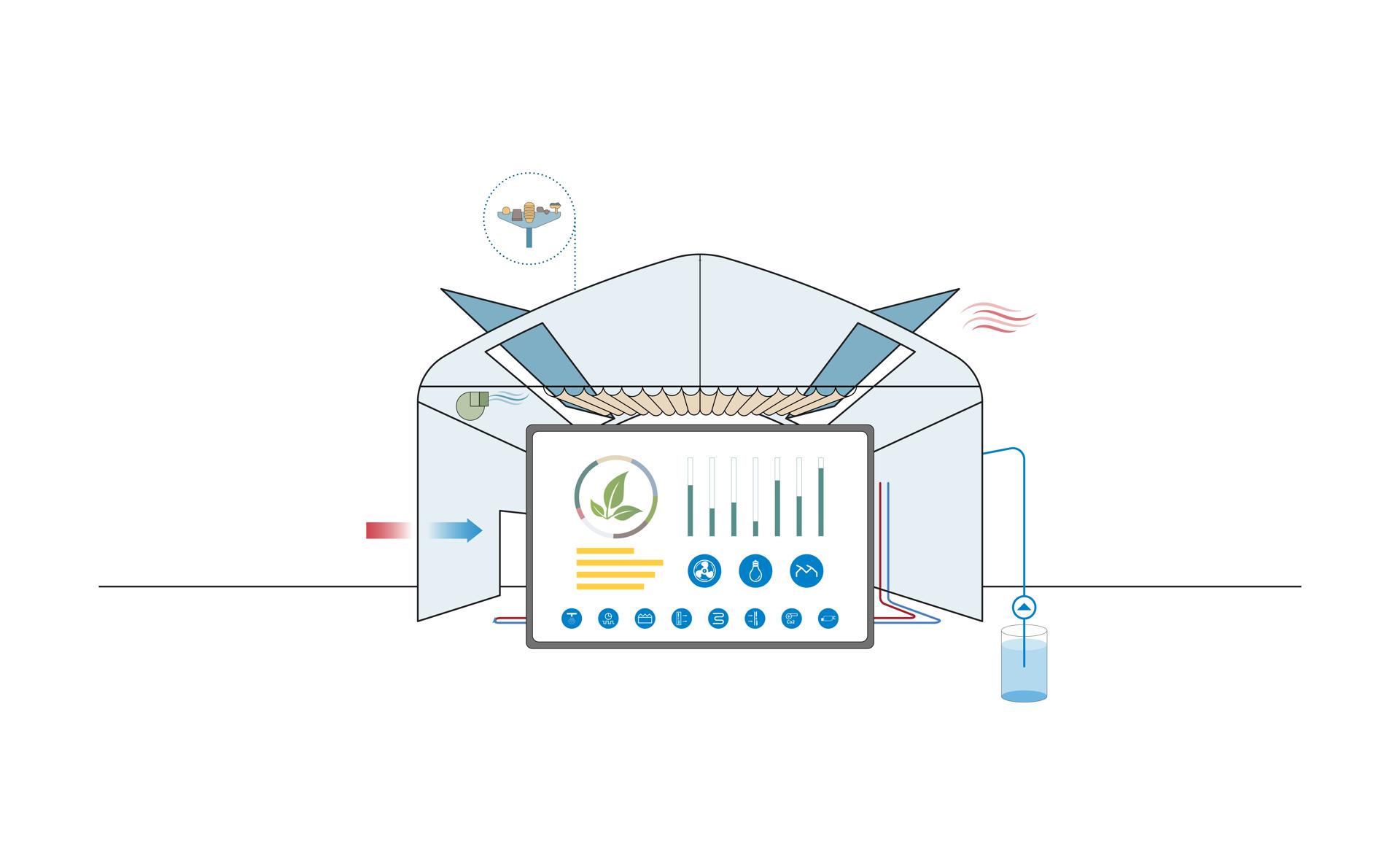

To ensure high-quality production it is fundamental to manage light, temperature and humidity in greenhouses. For this reason, Idromeccanica Lucchini has developed innovative climate screen solutions.

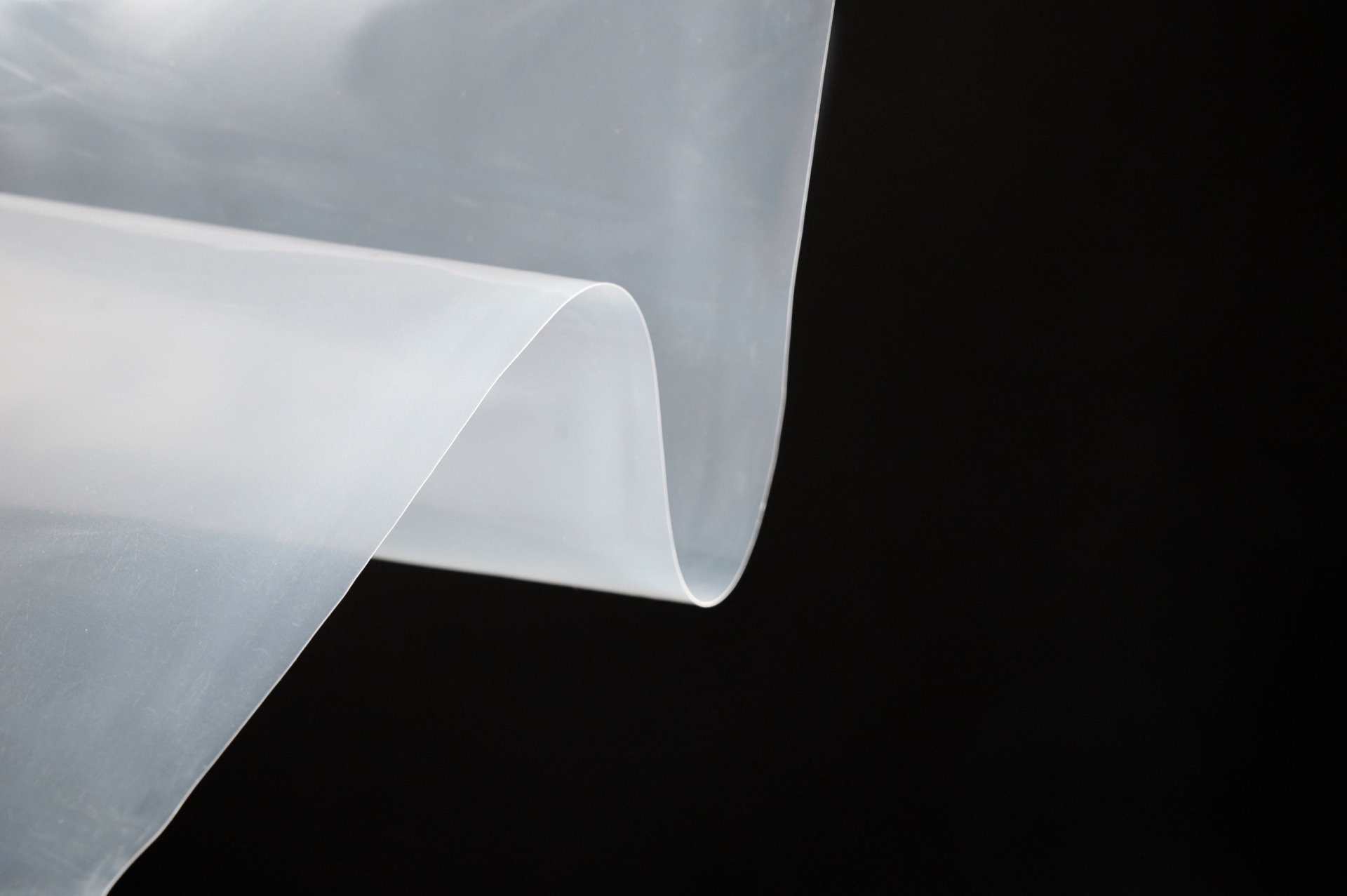

Climate screens for any need

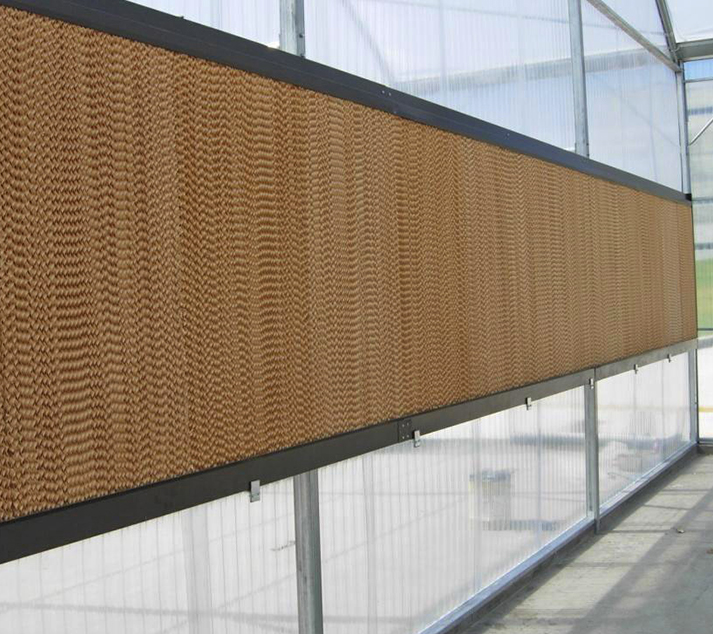

To suit different growing conditions, climate screens are essential in greenhouses. It is necessary to find the perfect climate screen solution according to the specific needs of the plant, for its health, its yield and to obtain the highest organoleptic quality. The company provides climate screens with light filters suitable for crops depending on whether they are vegetables, flowers or products for phytotherapy.

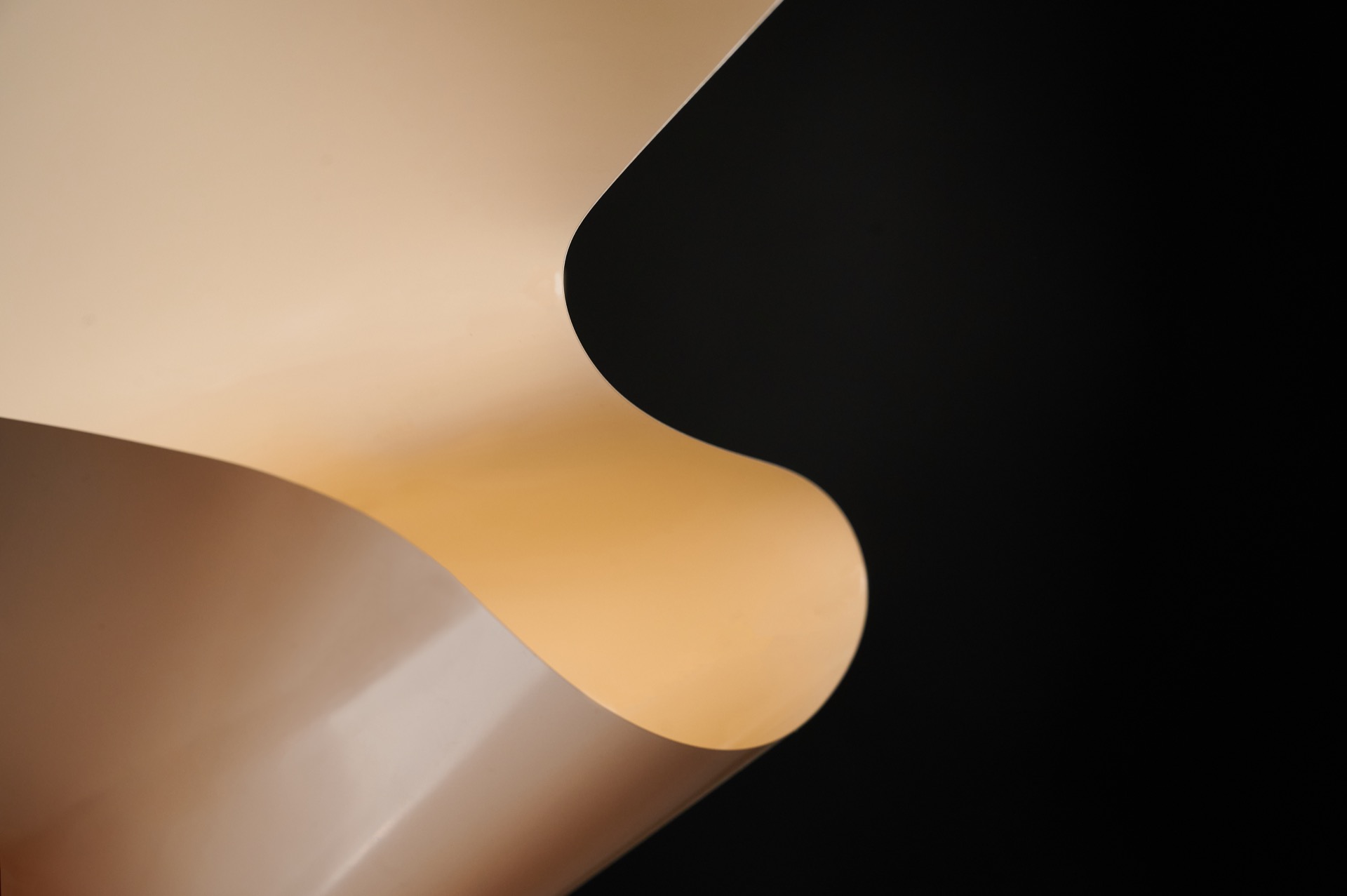

Idromeccanica Lucchini offers different shading-level screens: from total blackout to a 20% shading. Even in this case, the company can provide the customer with the right advice for the best climate screen solution.

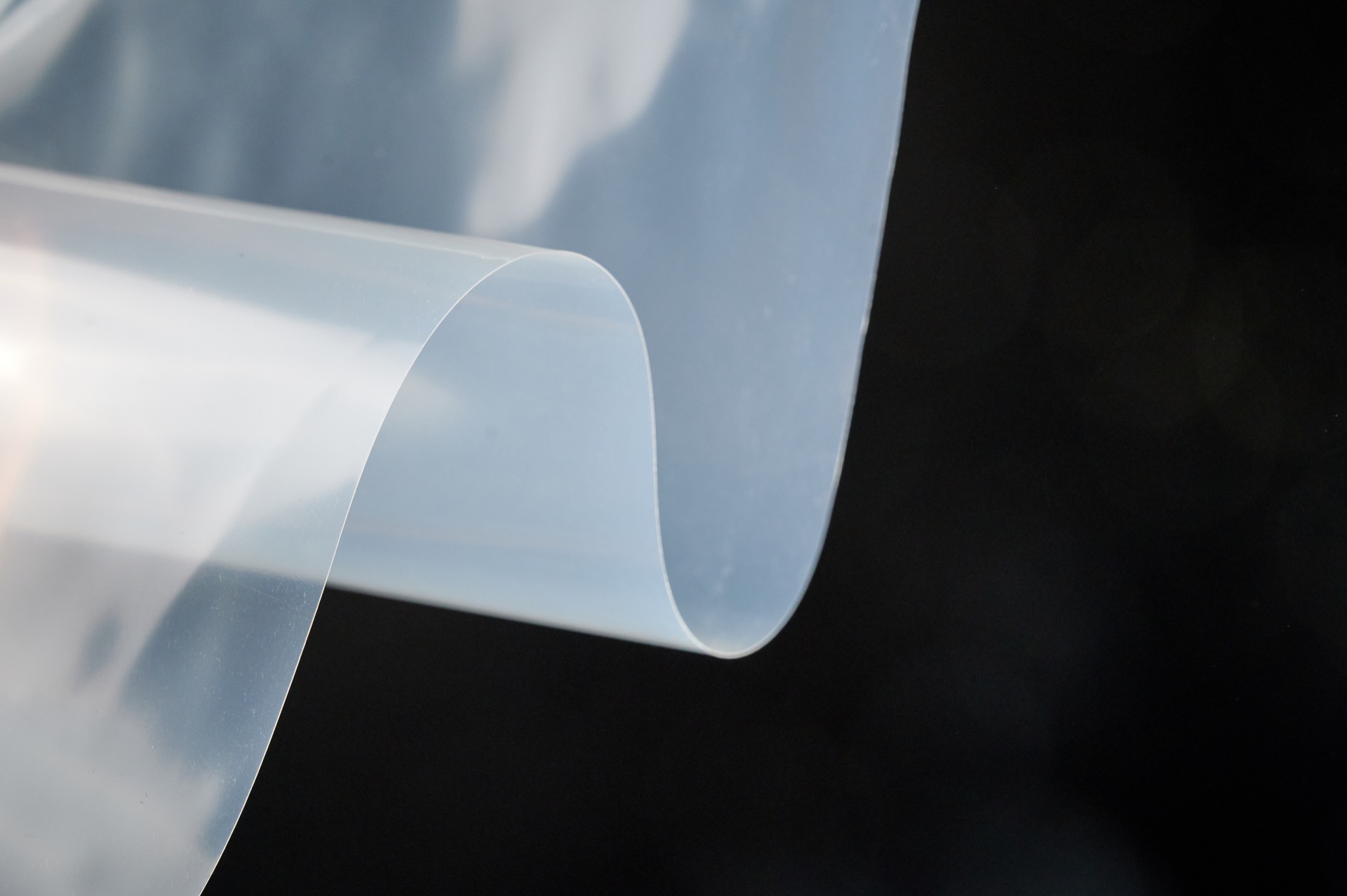

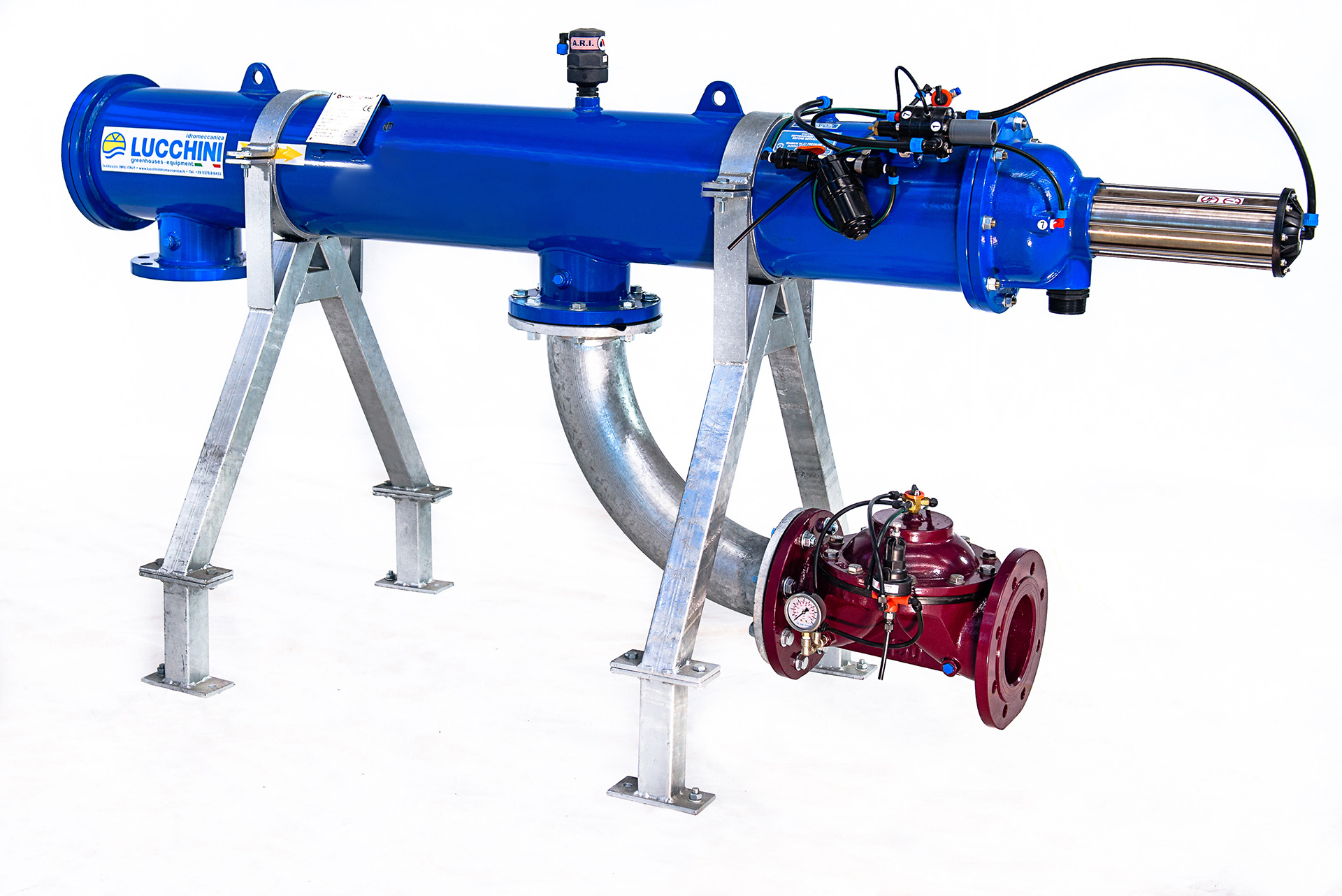

Each climate screen is moved automatically and the opening or closing is regulated by sensors that monitor temperature, humidity and insolation inside the greenhouse. The screen is independently opened or closed by the computer system depending on the conditions to be achieved. Also, the opening and closing of the climate screen is done by “bundling” the structure.

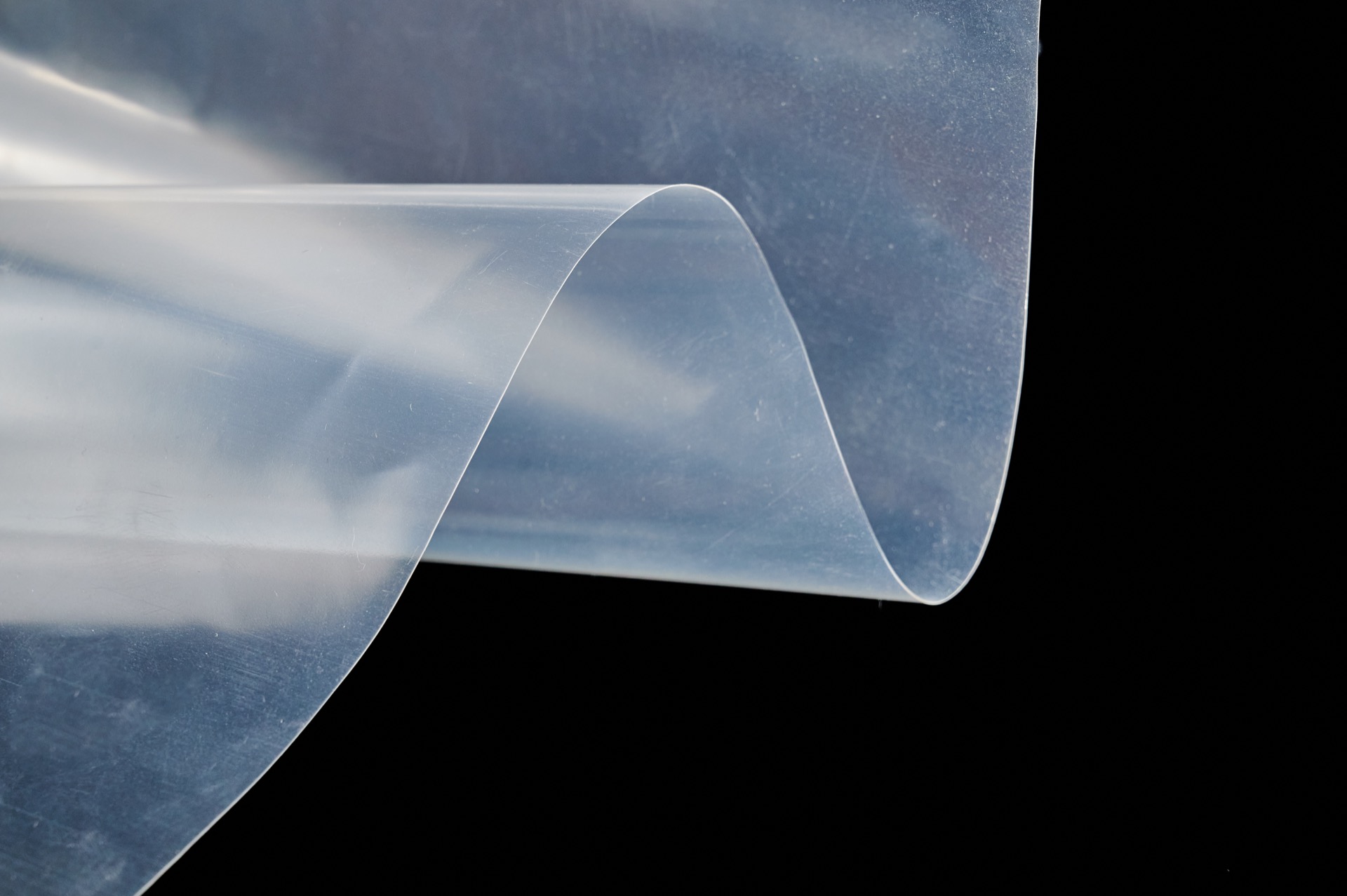

Energy saving screens

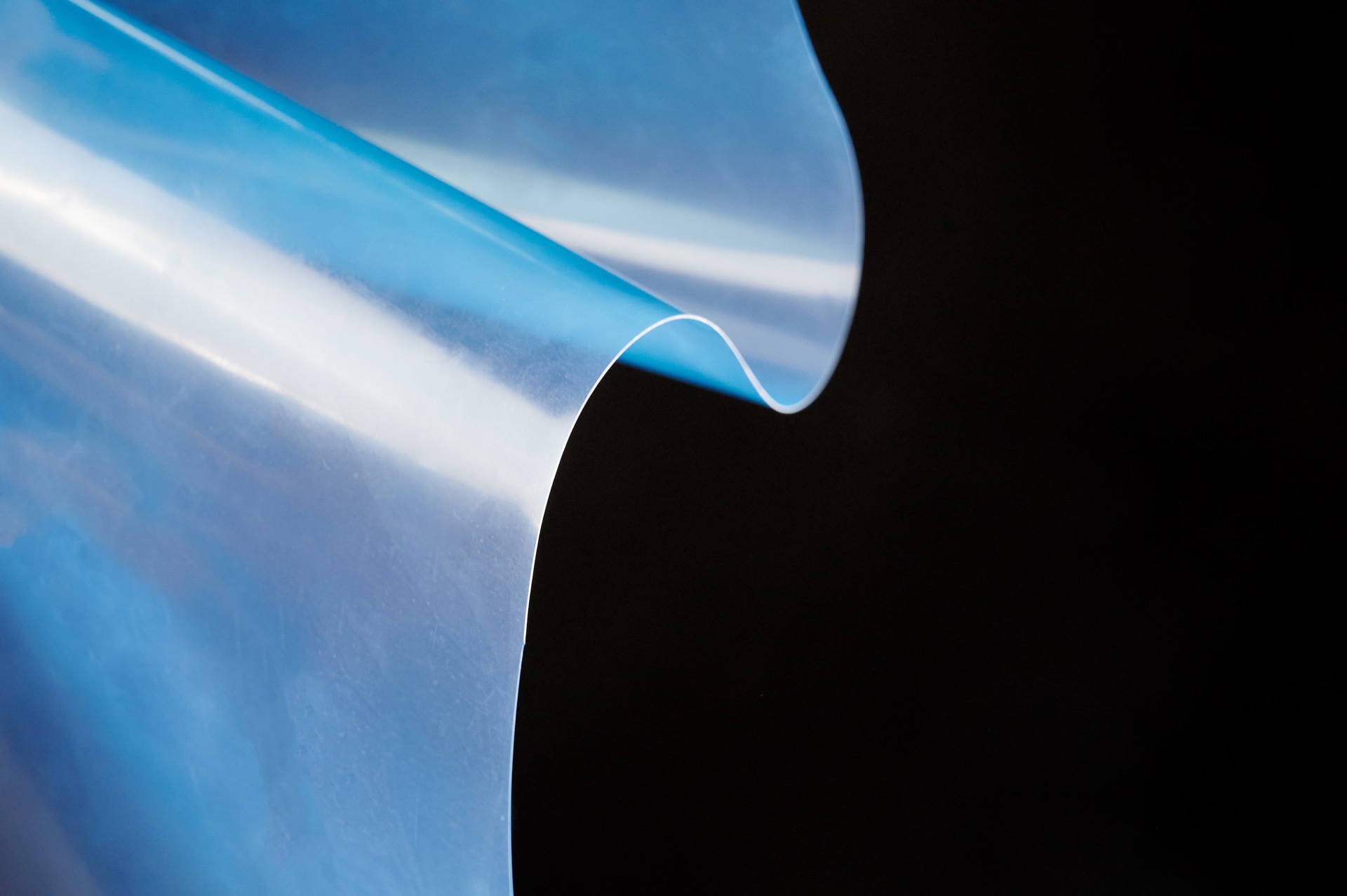

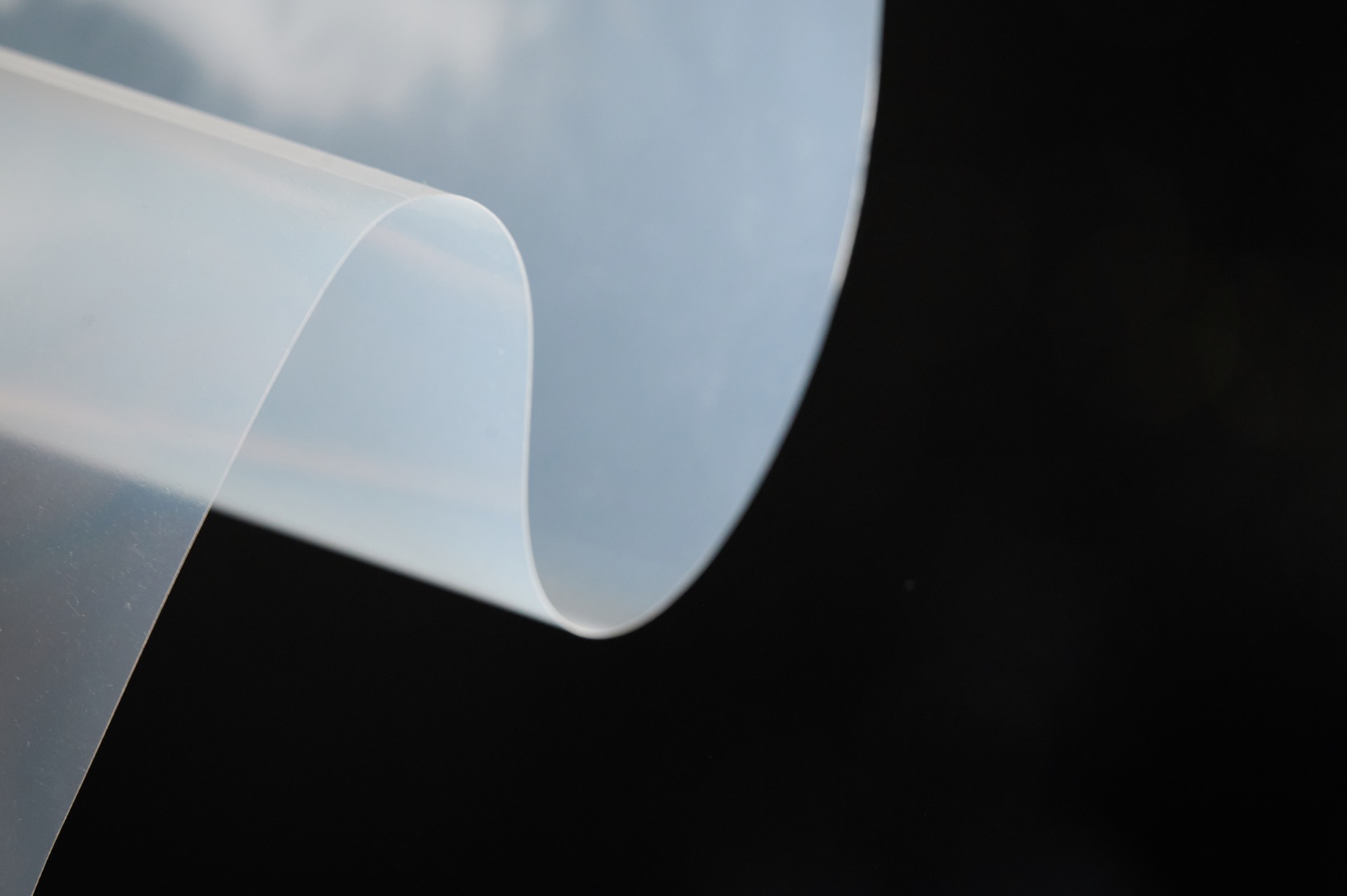

In the context of soaring energy and heating prices, dual screens provide considerable energy savings. Above the first screen there is a second, transparent, which reduces the internal heat dispersion and therefore, minimizing energy expenditure. So, there are considerable savings over time despite a significant initial investment. Precisely because it is possible to calculate and determine the energy costs for each project in advance, Idromeccanica Lucchini can advise its customer when and whether to use two screens to save even more.

Open or closed screens

Today it is possible to choose between open or closed climate screens, while until recently only the closed one helped people save energy. Over time, it was realized that this feature did not adapt to every climate and, above all, every type of plant. Opened or closed screens are purposefully selected and installed depending on the type of crop and specific needs, which are also studied according to the climate outside the greenhouse on the basis of altitude, latitude and season. In order to fulfill the customers’ needs, Idromeccanica Lucchini combines screens that reduce light distribution inside the greenhouse while allowing maximum airflow to achieve the ideal light and temperature for the crop. Nowadays, climate screens in warm areas have improved technology. These are completely white screens that do not overheat and cool the temperature inside the greenhouse.

Installation and automation

Usually, climate screens are mounted between one and three meters under the greenhouse tie rod. In some cases, such as in warm countries, the screen is placed beyond the roof of the greenhouse in order to keep the inside cool.

In a region characterized by hail and wind, it is better to place the screens under the greenhouse roof to ensure its integrity.

As already mentioned, screens are 100% automatic and operate through motors connected to sensors that read the light, heat and humidity parameters. The computer opens or closes according to the parameters that the grower, or the predictive system, has entered. The systems are more or less technologically advanced depending on the customer's needs. In greenhouses with ventilation or heating systems, the parameters are interconnected and therefore the screen operates with the other systems to increase efficiency. The synergy of the different systems provides energy savings of between 40 and 60%.