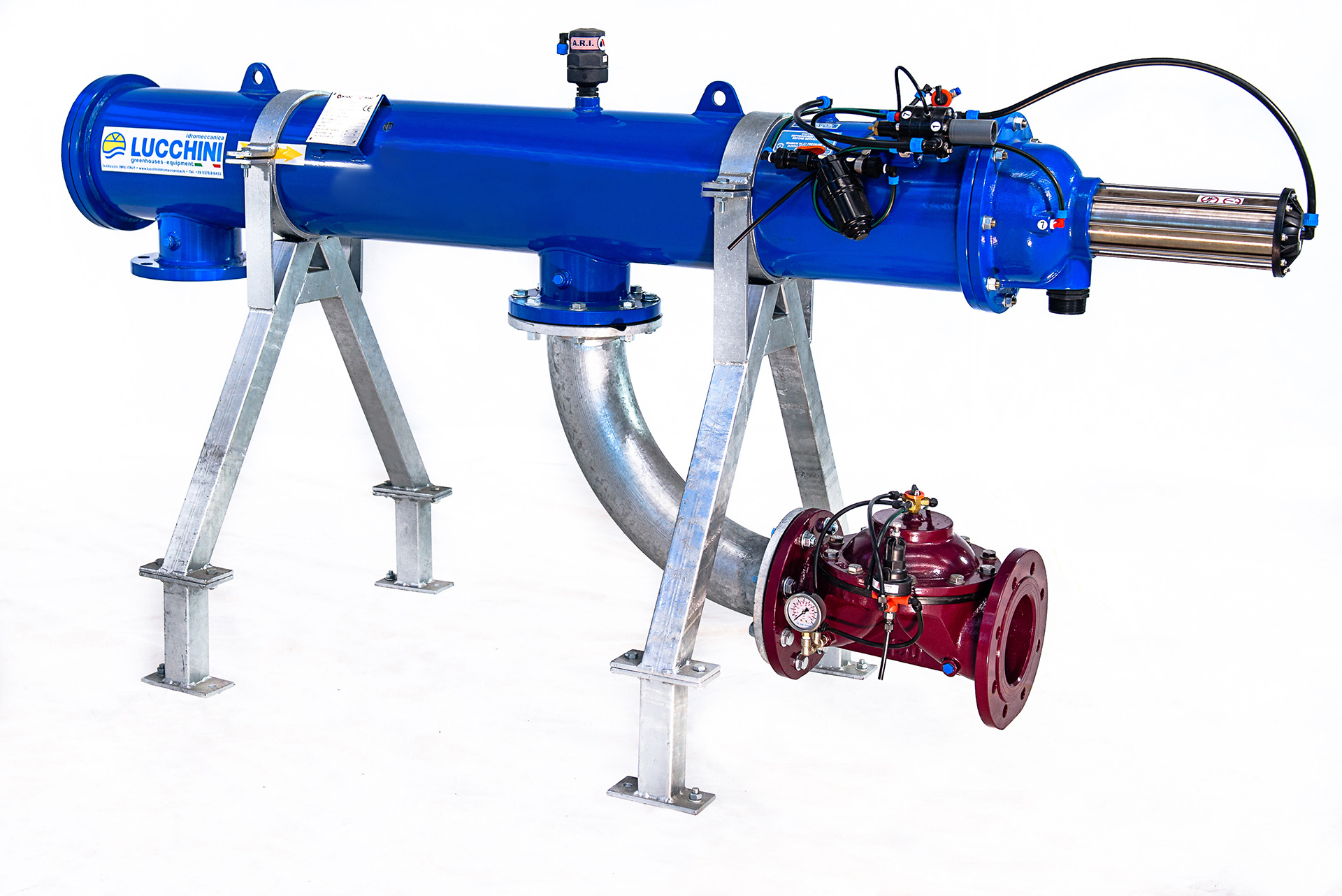

Our manufacturing process is the result of years of industry-specific experience and improvements in planning, logistics and processing of plastic, metal and electronic materials. Idromeccanica Lucchini carries out all its projects following strict protocols and optimized workflows. To ensure maximum quality standards are met, Idromeccanica Lucchini develops tailor-made projects based on the customers’ specific needs.

Our project management process: from the engineering phase to its implementation

After the engineering phase, Lucchini Technical provides the production department with a detailed bill of materials identifying the components needed in building the greenhouse, the updated list of materials and the processing and installation times. Once the project has been studied by Lucchini Technical, all departments (welding, calendaring…) are informed of the next processing steps including the ordering of raw materials. Each order requires the use of specific materials and different processing techniques precisely because every project is unique, and must be treated as such. The production manager checks every step of the manufacturing process from the bill of materials to the finished product which is then assembled on site. Every step undergoes strict quality controls throughout the entire manufacturing process and it is ensured the respect of deadlines.

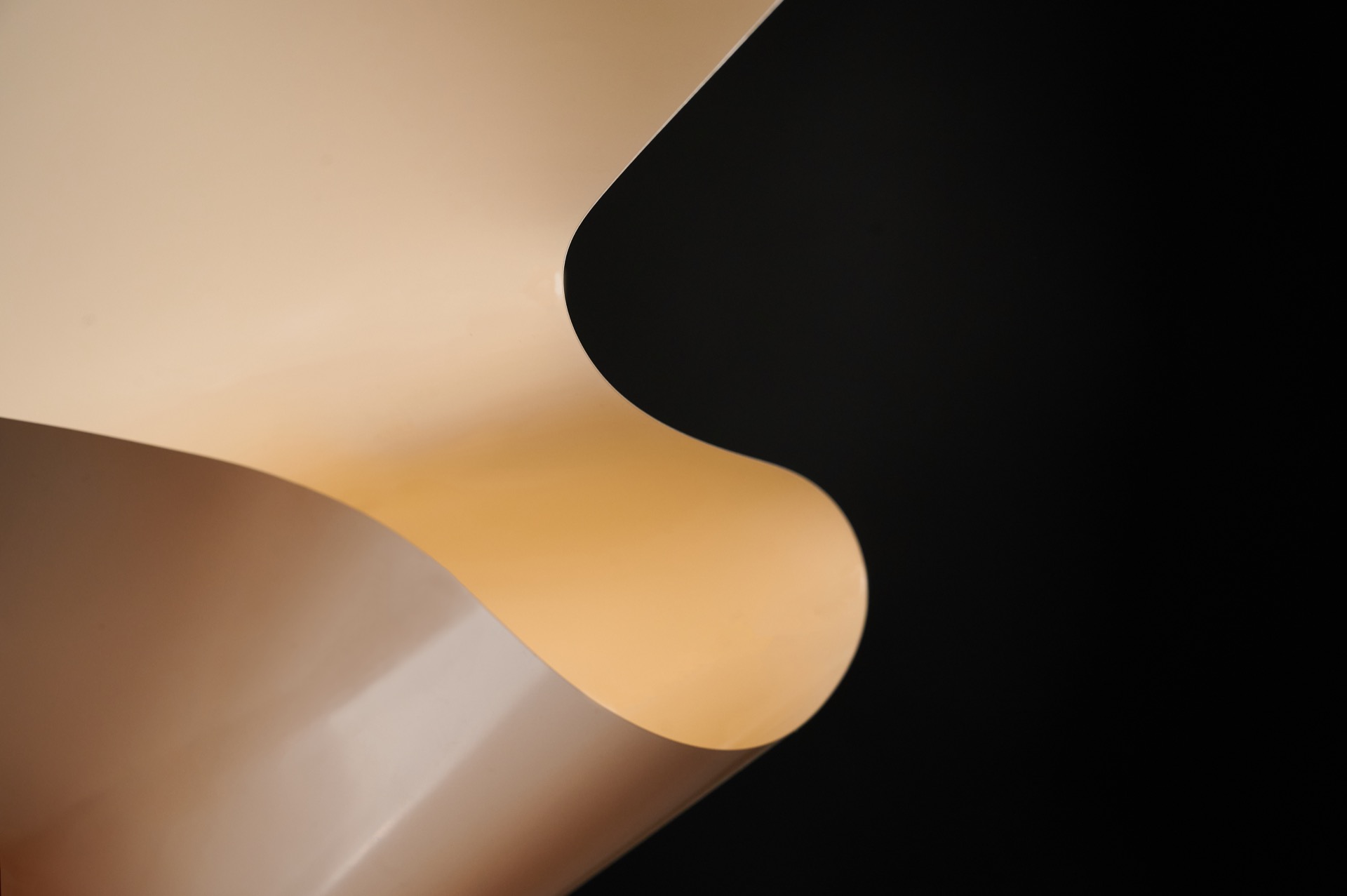

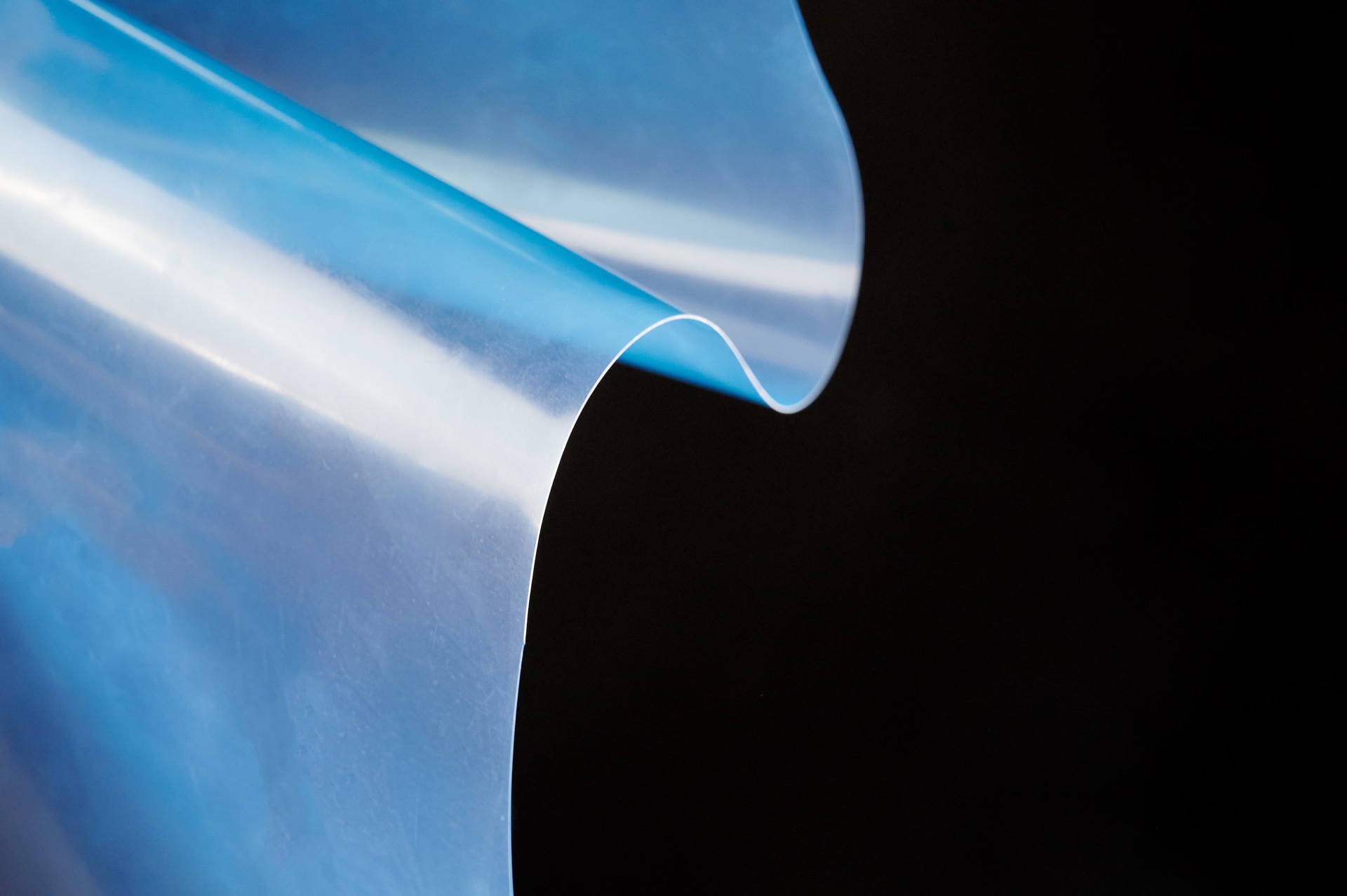

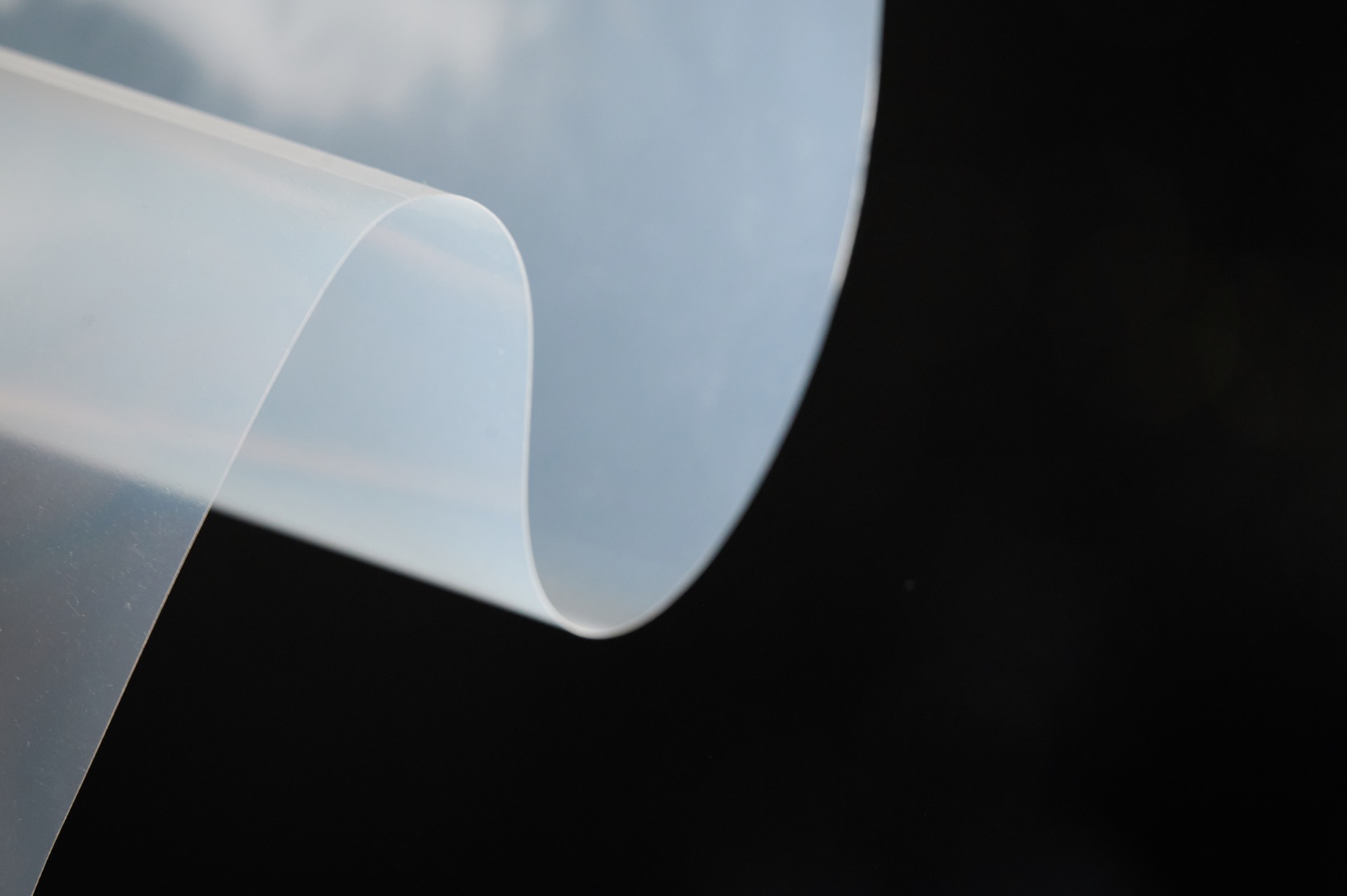

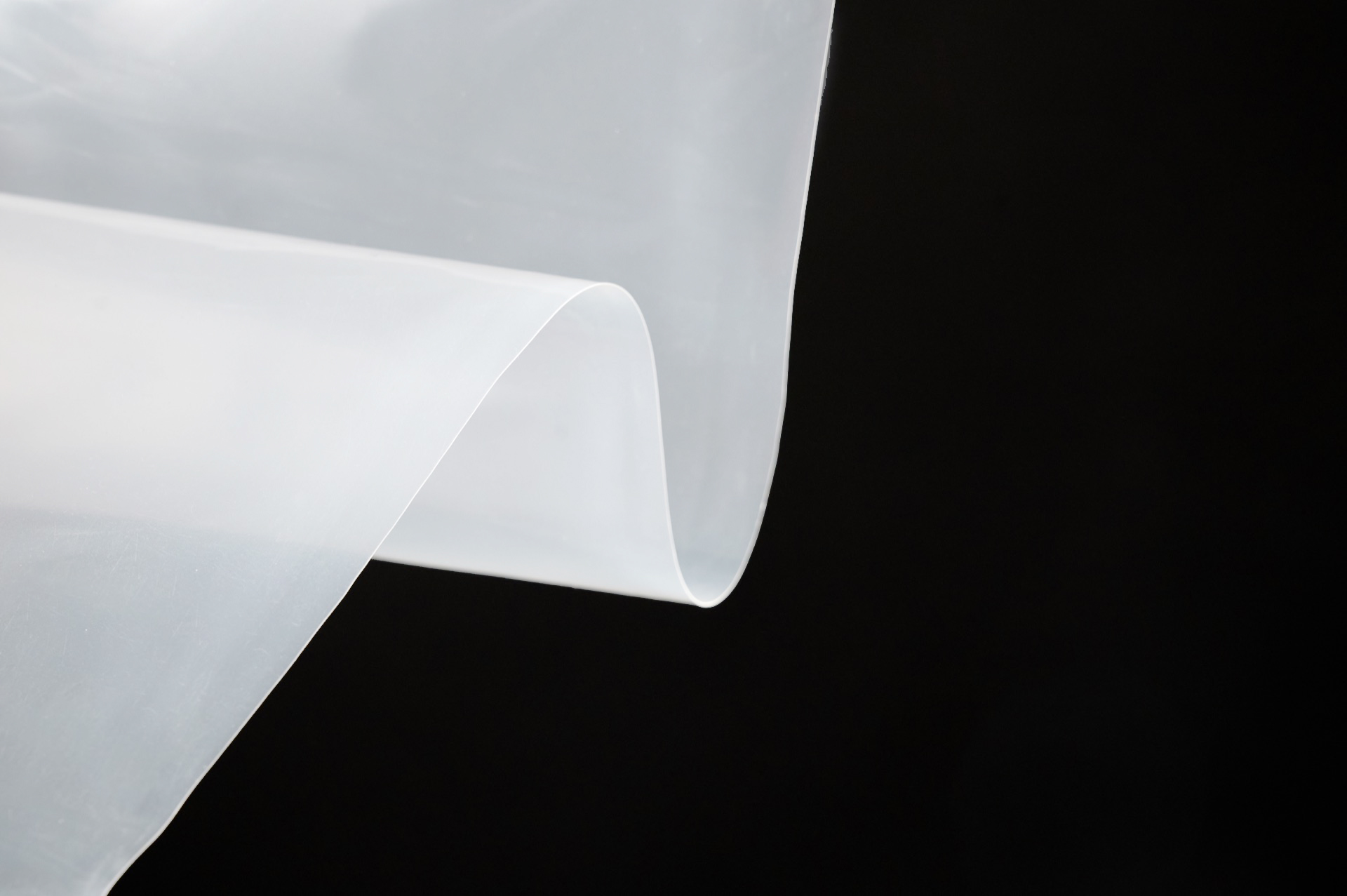

“Hand-crafted” and “tailor-made” products

Idromeccanica Lucchini supplies greenhouses and equipment all over the world and has developed world-class expertise in fields including floriculture, vegetable production, private citizens and big companies, from Italy to the Caucasus heights. Therefore, it is necessary to adapt production to the harsh geographical conditions and the specific customer needs. Consequently, metal materials are shaped differently depending on the type of greenhouse, from private to large-scale industrial. Much of the processing is therefore done manually, because automation cannot replace human experience. All this is delivered on time meeting the project requirements.

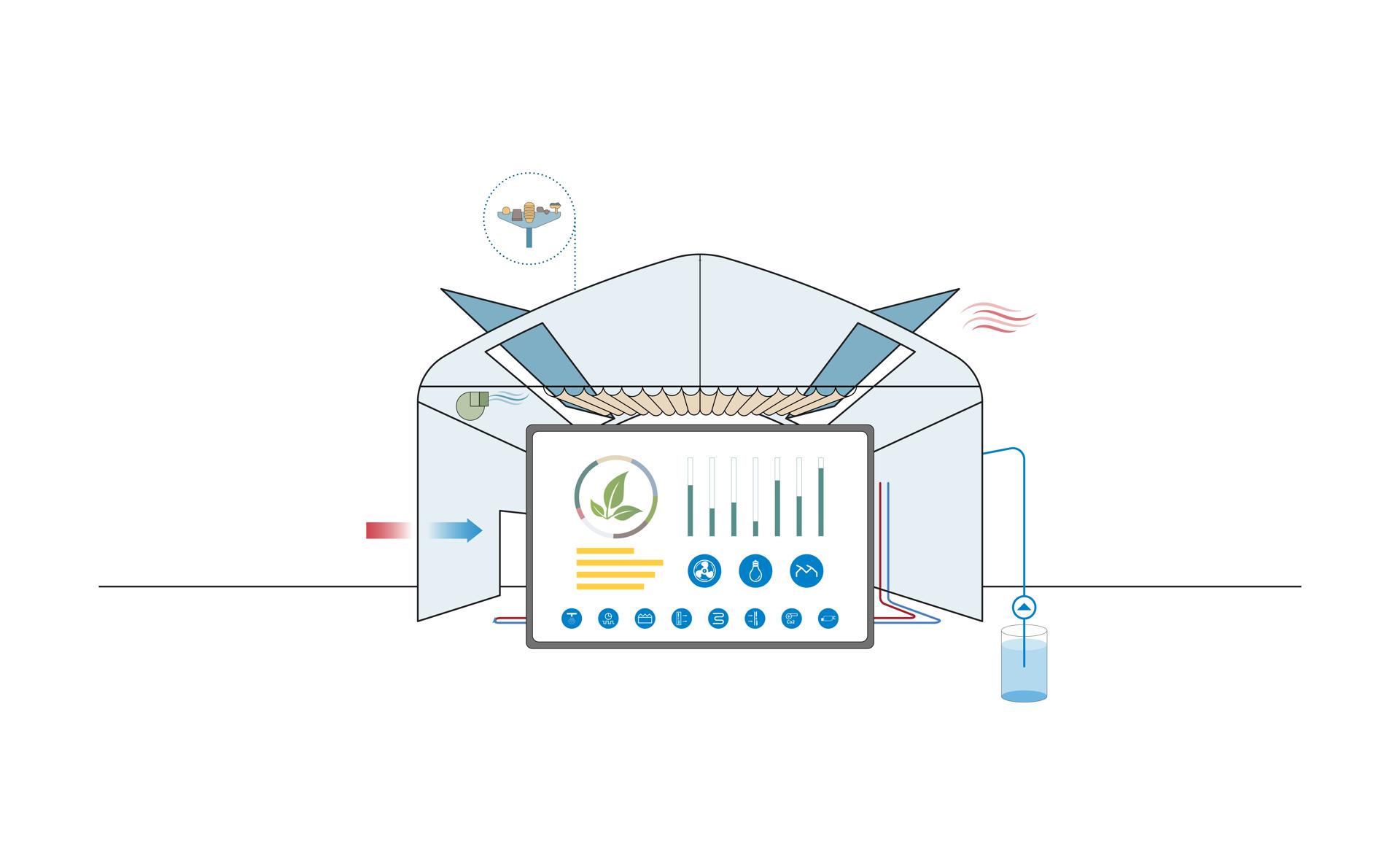

Automation and logistics based on cutting-edge technologies

Idromeccanica Lucchini has computerized systems for moulding and welding processes to ensure the utmost precision and efficiency. The company is thus able to produce perfect, stable and durable load-bearing structures. In recent years, as the company’s business has grown, Idromeccanica Lucchini has implemented internal logistics, both in the storage of incoming materials and raw materials, and in the storage of completed products ready for delivery. Consequently, new wide spaces have been created and tracking protocols have been drafted for each processing phase. Everything is strategically stored so that materials can be handled and sorted quickly and efficiently.