Japan cannot be exactly named as the Tomato Homeland, even more the most northern part of the country where snow and cold are the master. And yet, especially in recent years, the cultivation of this solenacea has attracted a lot of interest in the country of the rising sun and also Idromeccanica Lucchini has helped to study and improve the most modern and innovative techniques for the cultivation of tomato in Japan.

A greenhouse for tomato

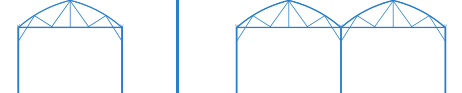

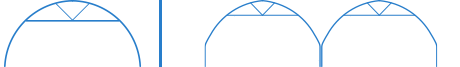

The intervention of Idromeccanica Lucchini took place in the territory of Okadama, near the prefecture of Sapporo in the region of Hokkaido in northern Japan. In order to cultivate the tomato in such a harsh climate it was necessary to build a greenhouse of 1,200 square meters that could ensure an adequate microclimate to the proliferation of the plant. For the intervention was chosen as the basis for the greenhouse Multyatlantic Evoluzione with spans of varying width between 9.60 and 12.80 meters.

Automation, Research and Development

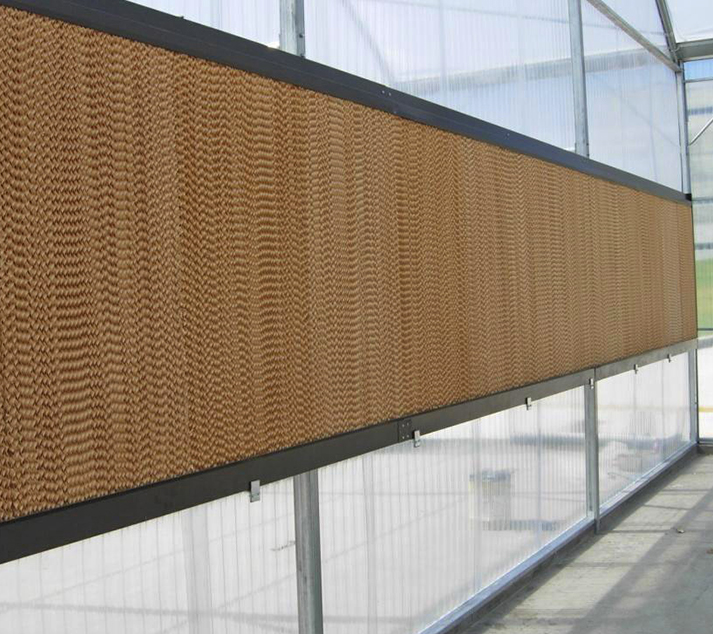

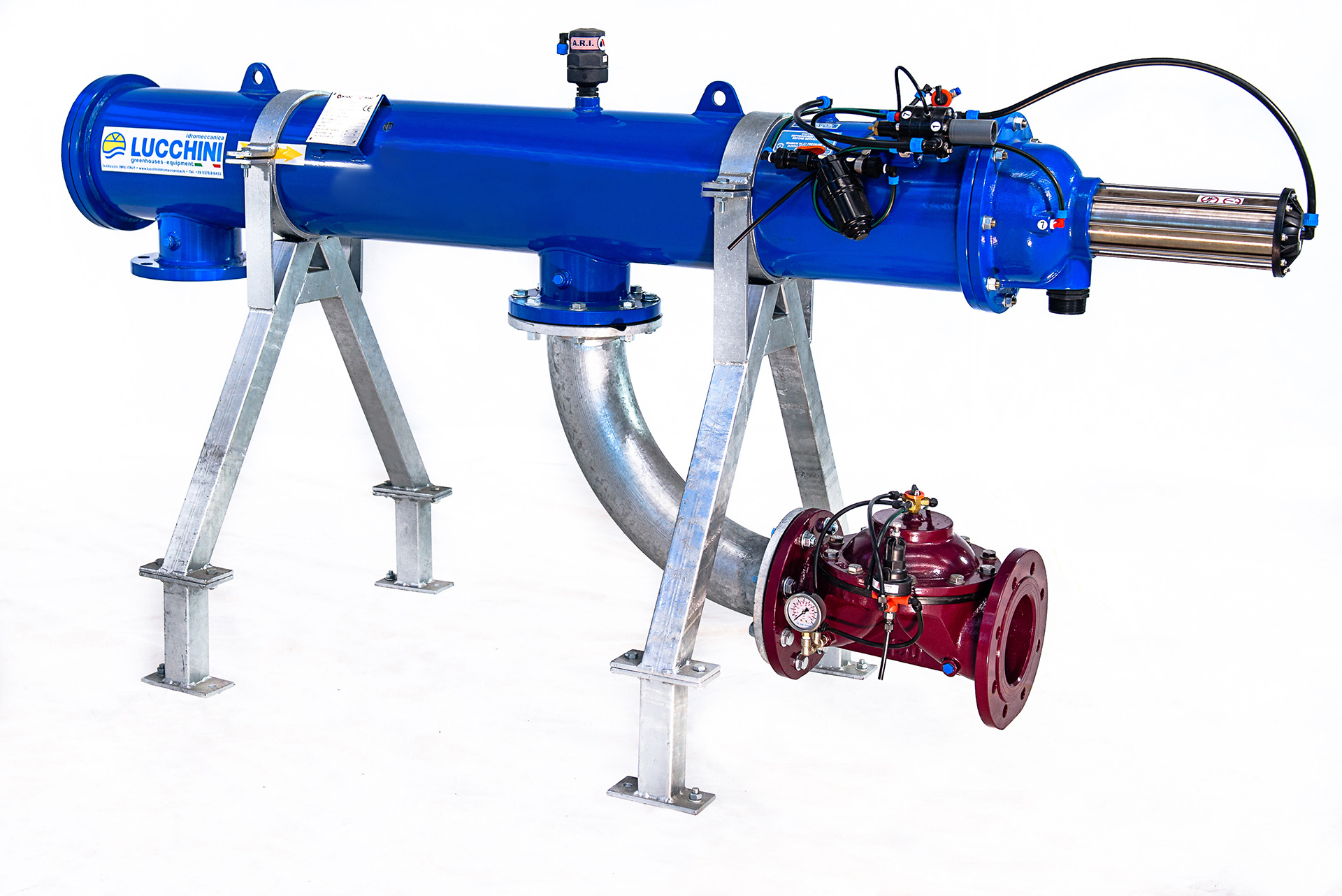

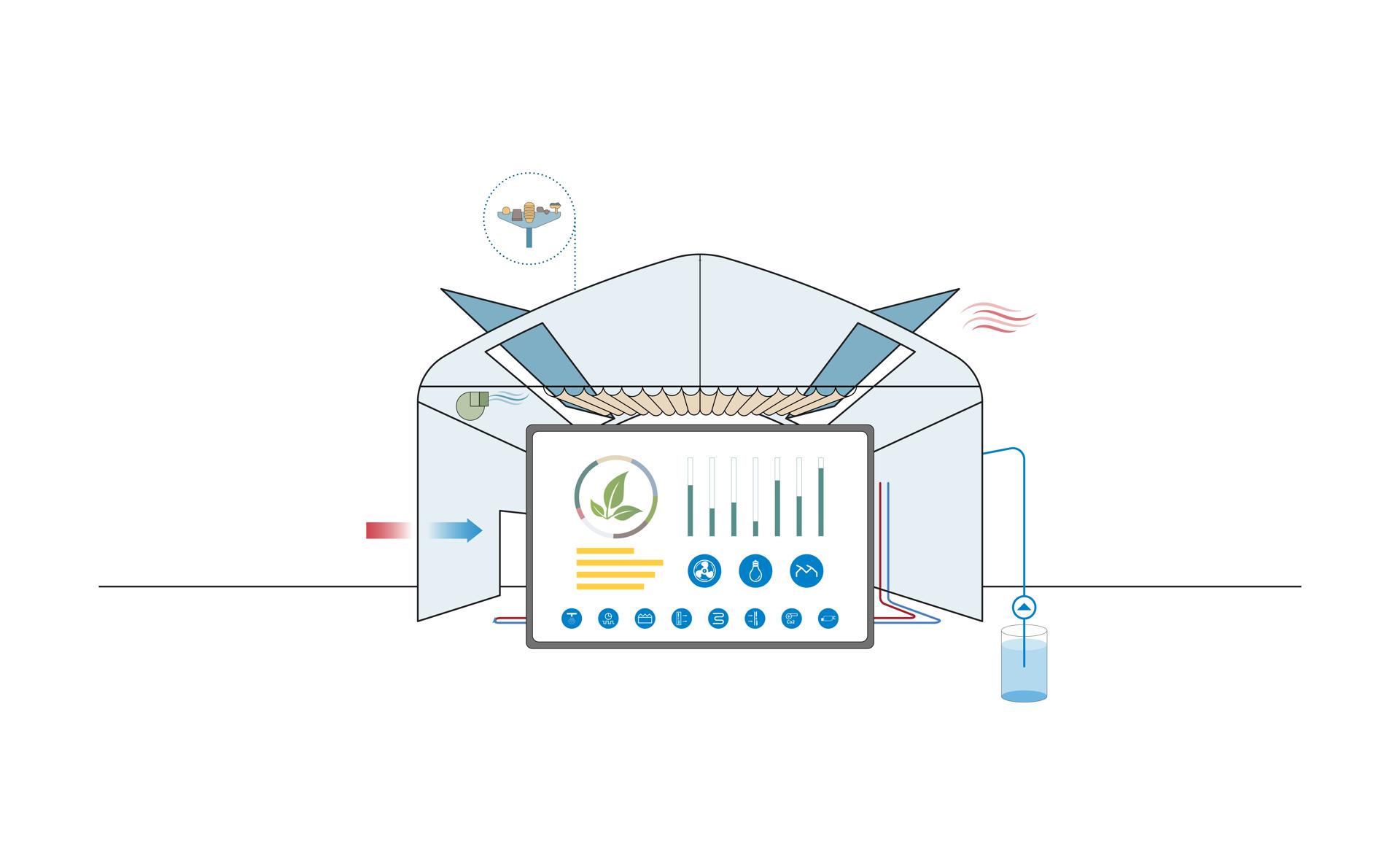

The intervention in Japan was born thanks to a collaboration with the Hokkaido University Agronomic Division for the inclusion of tomato cultivation. The first stages of the research mainly focused on growth steps, in order to establish the procedures best suited to the health of the seedlings and their yield. Many were the adopted technical solutions for the construction of the greenhouse, a real pilot of a series of future greenhouses, and a result of careful experimentation. The tomato in the greenhouse is soilless grown on a rock wool substratum, placed on small channels suspended and equipped with basal heating. The greenhouse is heated with water heating pipes to melt the snow (which would otherwise cause great humidity inside the greenhouse) and also to increase the internal heat, while passive ventilation is guaranteed thanks to a double window. Inside it was placed a screen, which can be opened and closed automatically, to adjust the light gradient. The screen has two functions: shading and light regulation and, of thermal "coat" and insulation, since in Hokkaido climate 80% of the temperature range occurs from the roof. The various automated systems are able to keep 18 C at night and 28° C at day inside the greenhouse, to ensure a high-performance growth of the seedlings and the correct opening and closing of the stomata.

The Japanese Lesson

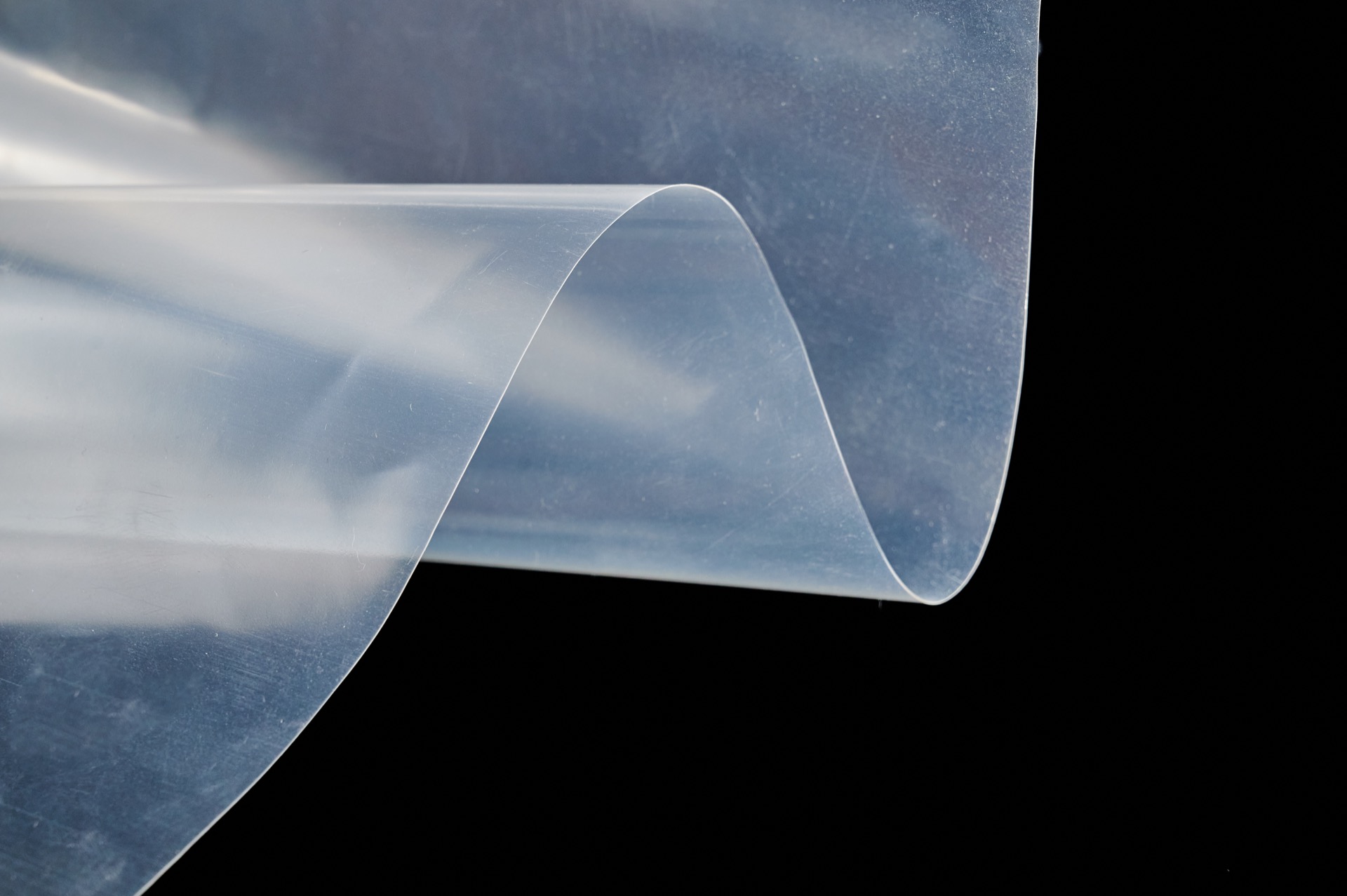

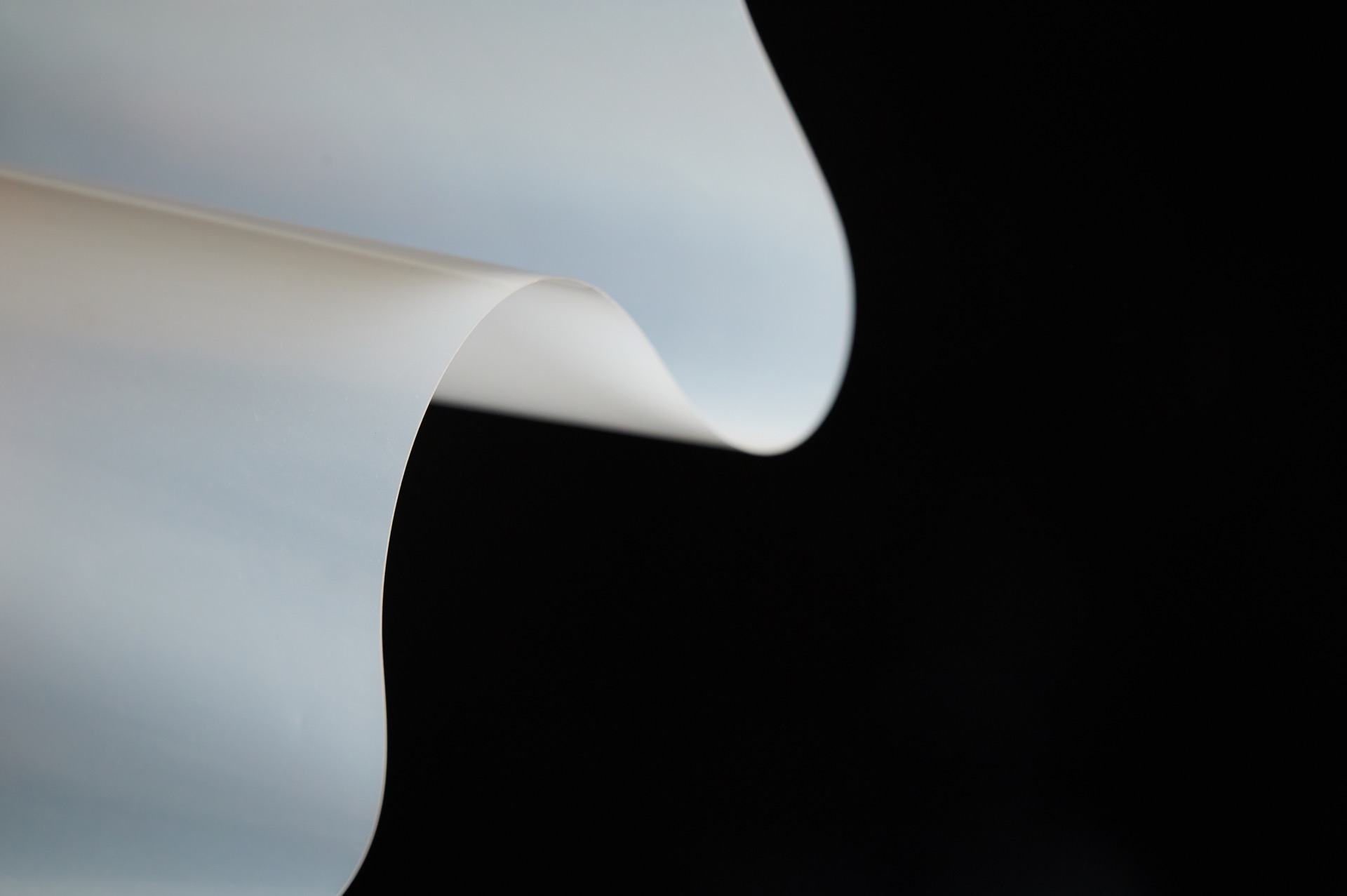

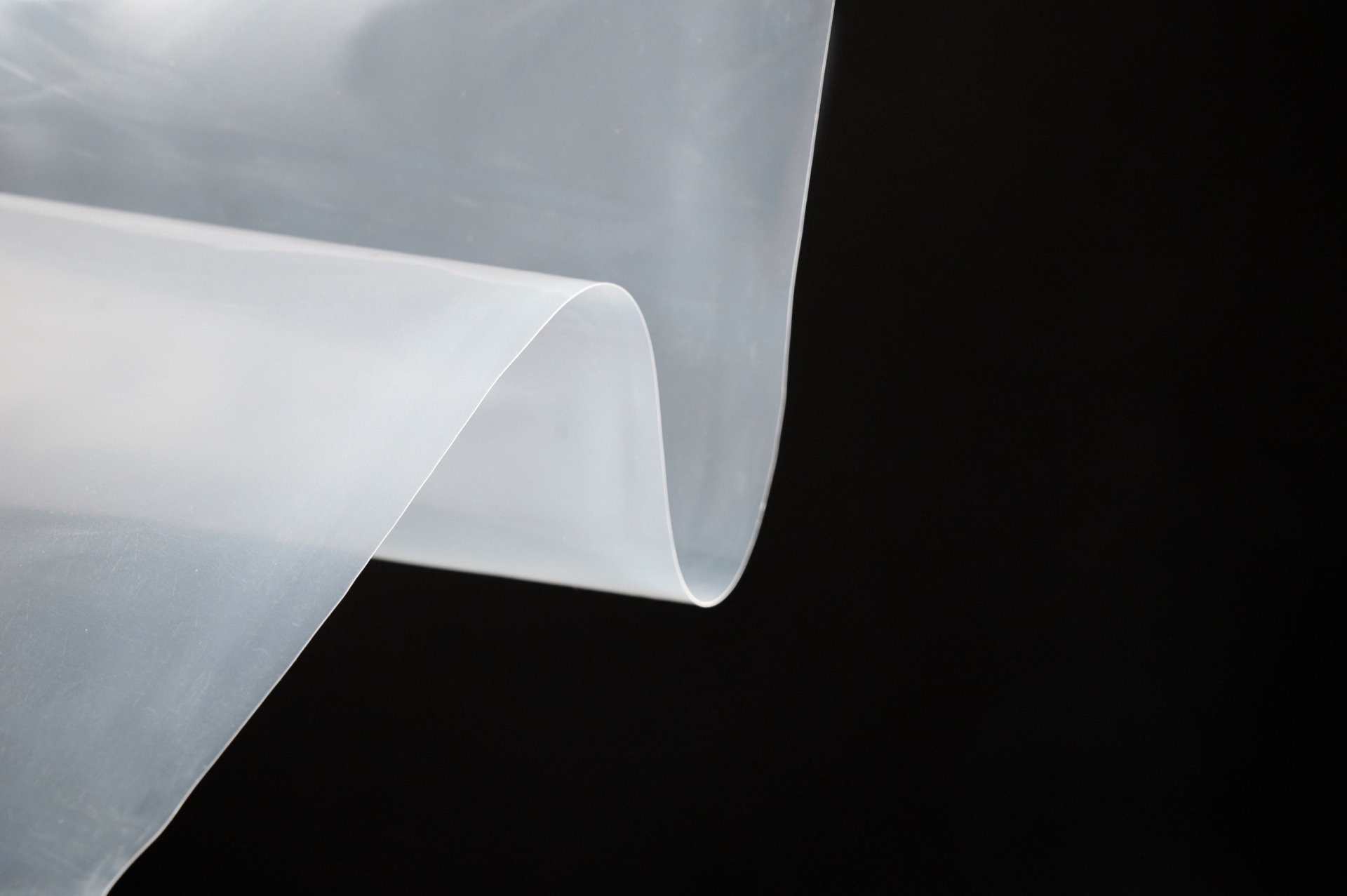

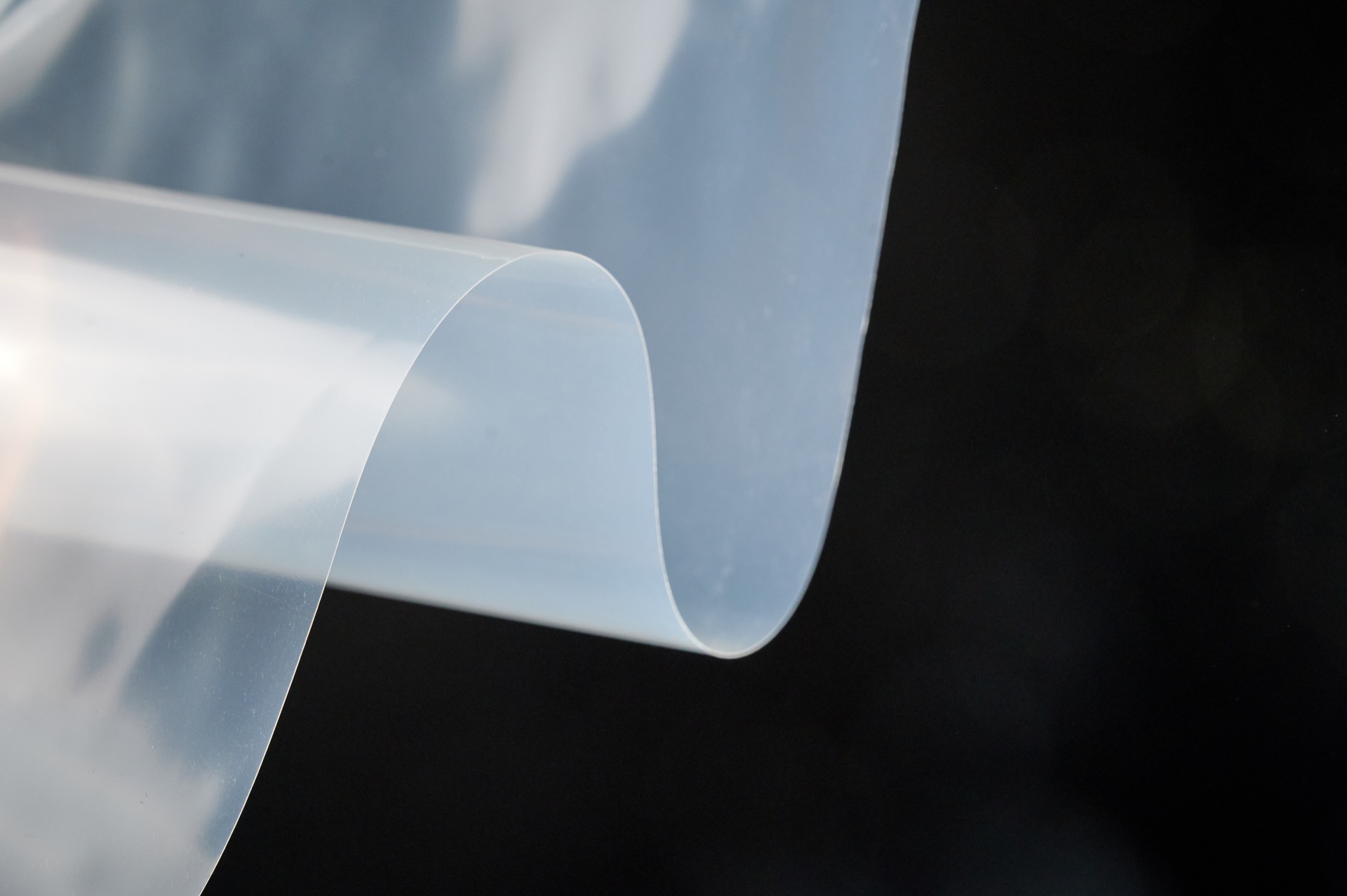

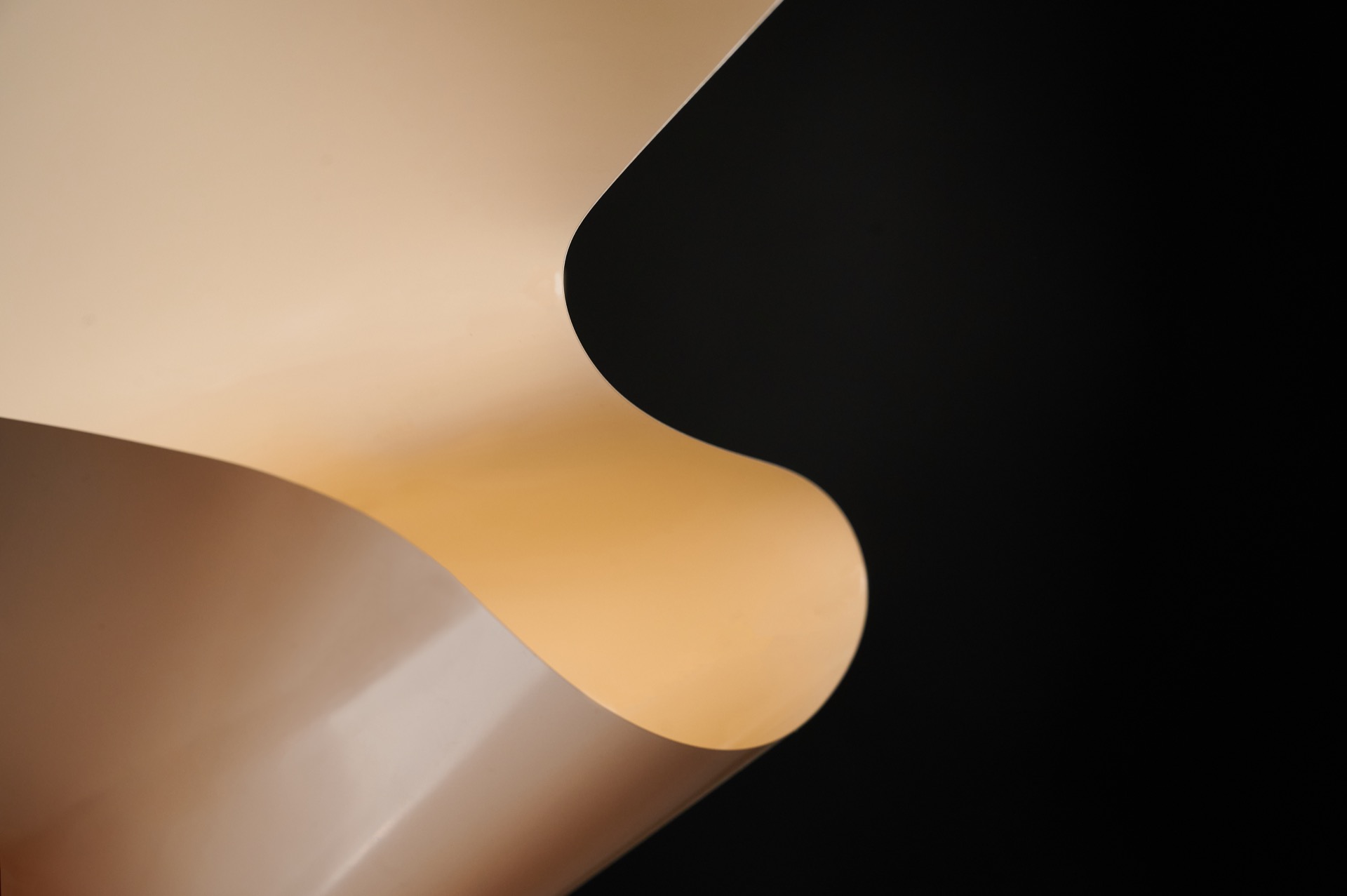

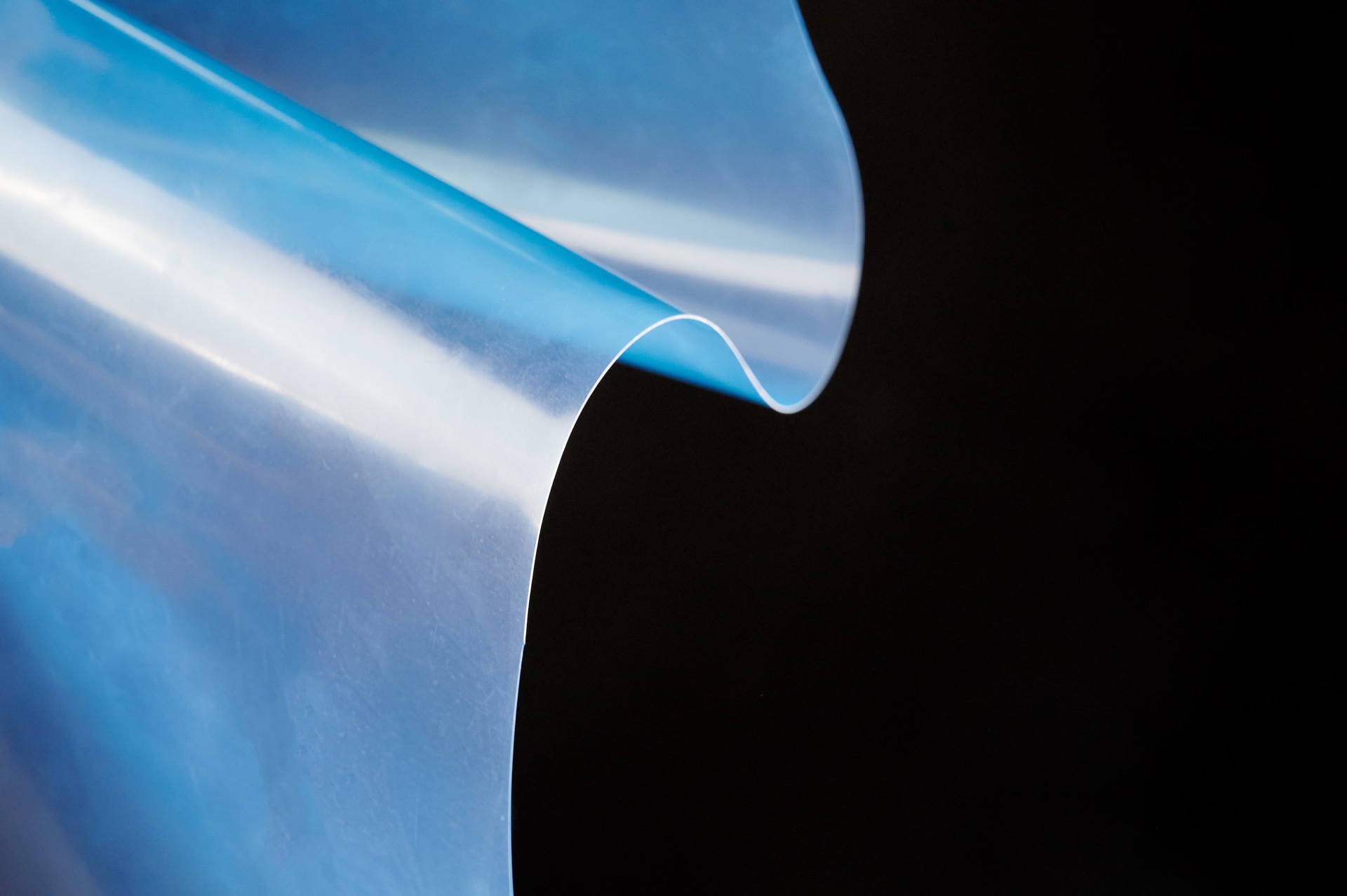

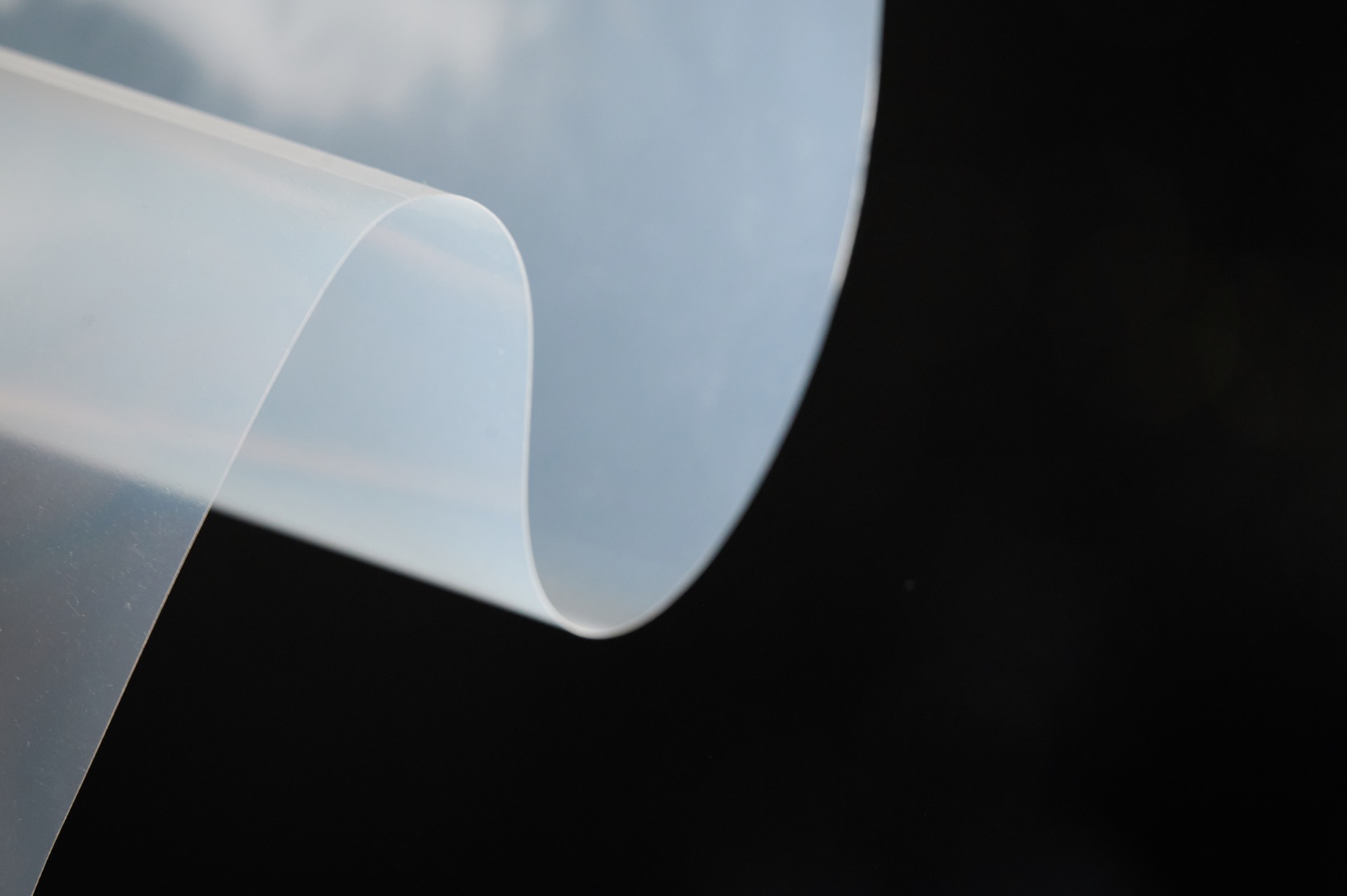

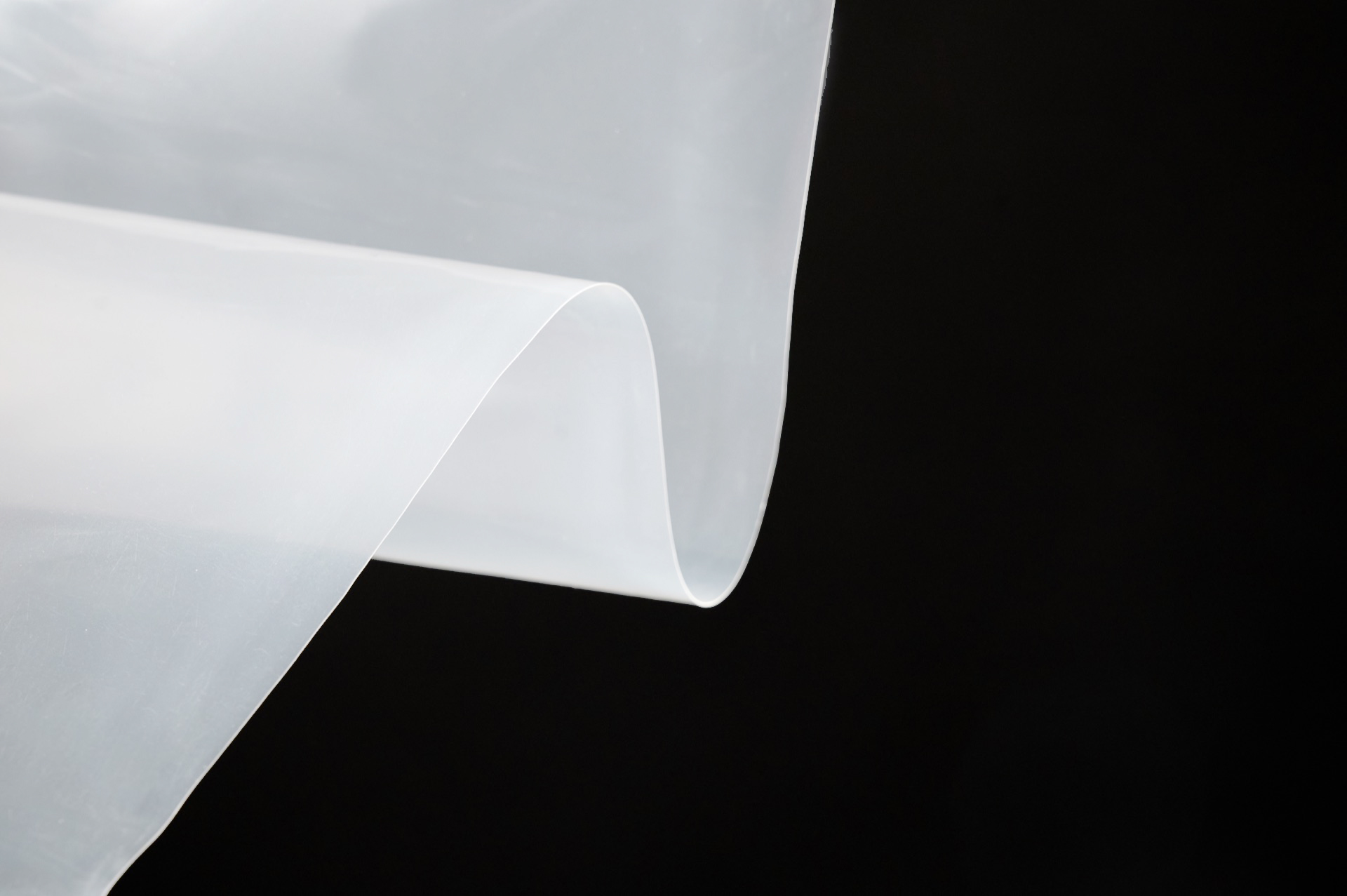

Being obliged to work with Japanese materials and customs, Idromeccanica Lucchini has been able to adapt in a short time to different techniques that it has made its own fastly and with professionality. In Japan, in particular, roof sheets are made of teflon ETFE which, compared to our EVA polyethylene, has the advantage of having a light transmission equal to that of the glass, to be anti-flame, anti-dust and to have a duration of about 20 years. The sheet, made of modules and not coils, must be fixed on site with long-lasting fixings. The structure of the greenhouse was then made by Idromeccanica Lucchini in order to adapt to this specific roof cover. The ETFE teflon gives a large bright opening on cold and sunny days of Hokkaido and, to compensate for too much radiation on clear days, below has been prepared an open and close screen to balance the brightness.

Built on customer needs

The greenhouse, able to guarantee the perfect climate for the all year round tomato, is a project that has opened to Idromeccanica Lucchini many commercial implications in the rising sun. Built to the customer’s needs, the greenhouse had to meet two main requirements:

• Being very high with 9 meters total height with rigid wind and snow parameters dictated by the climate of the region.

• Respond to severe seismic parameters.

For Idromeccanica Lucchini it is a point of pride to have being chosen for such an ambitious project. Before delivery, the greenhouse was severely tested for both seismic impact and weather stress together with the engineers of the Hokkaido University and no stress was able to put the structure of the greenhouse in suffer. The great work carried out in close contact with the university’s engineering team for such an non-standard product, meant that Idromeccanica Lucchini matured new products to be offered to other customers on the Japanese market and beyond.

The learned lesson

Agreed interventions with the engineers have made it possible to lighten the greenhouse structure of exceeding material and to study technologies that maintain its integrity with greater lightness. The simplification of structures has perhaps led to a new generation of products that could only be reached thanks to the ability of Idromeccanica Lucchini to create innovation through collaboration and attention to the customer, which Idromeccanica Lucchini has always done with its Italian customers.