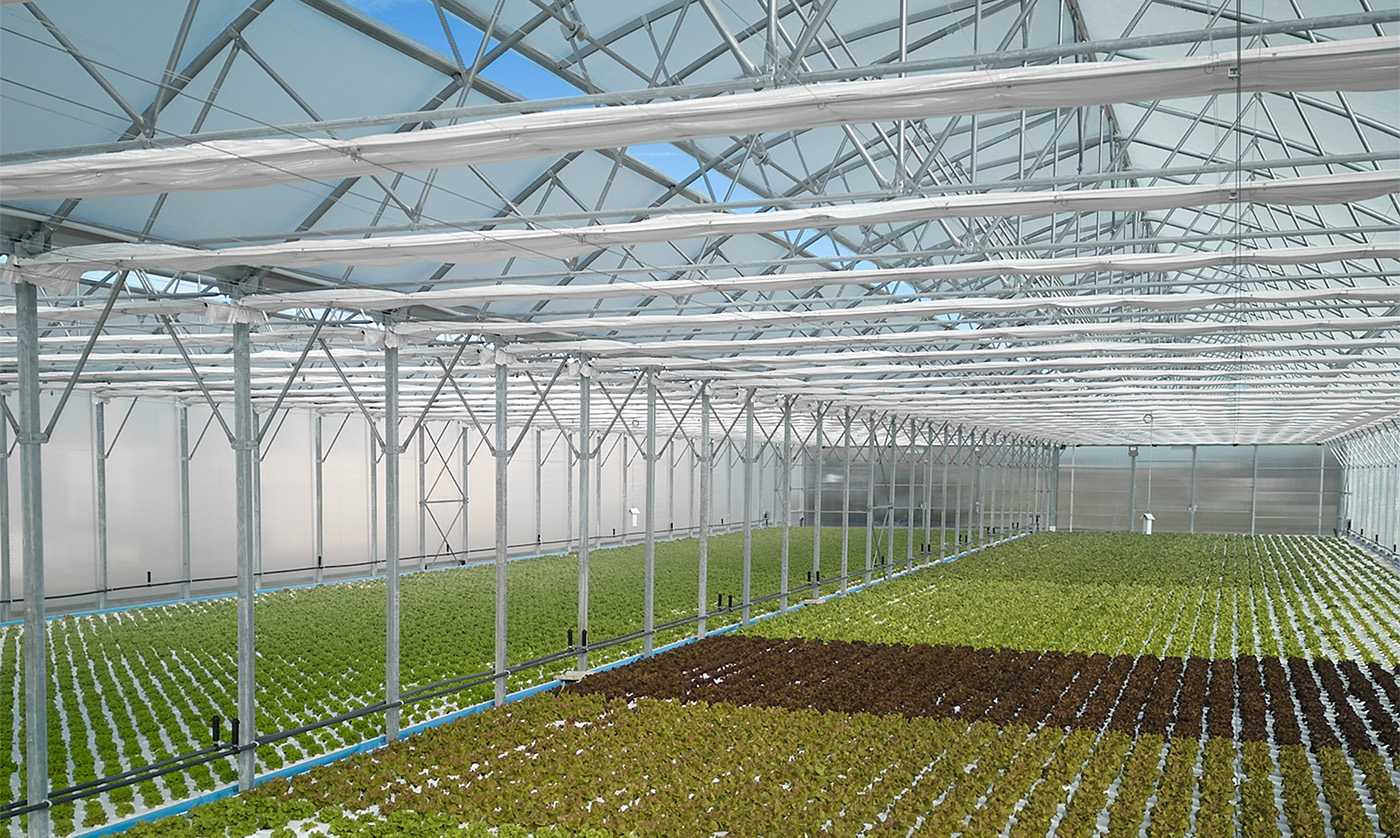

Idromeccanica Lucchini has created the largest floating system installed so far by our company in Emilia Romagna region. The chance got in 2023 for a consortium named Agribologna, in Cesena area. The plant is capable of producing a wide range of horticultural products, including lettuces and is developed around the Multyatlantic Evoluzione model. The greenhouse is equipped inside with a totally hydroponic floating system.

The floating system

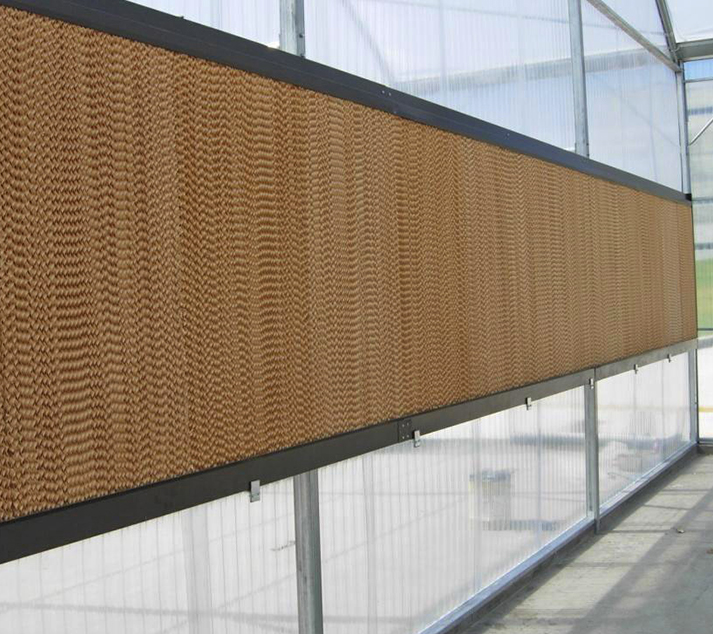

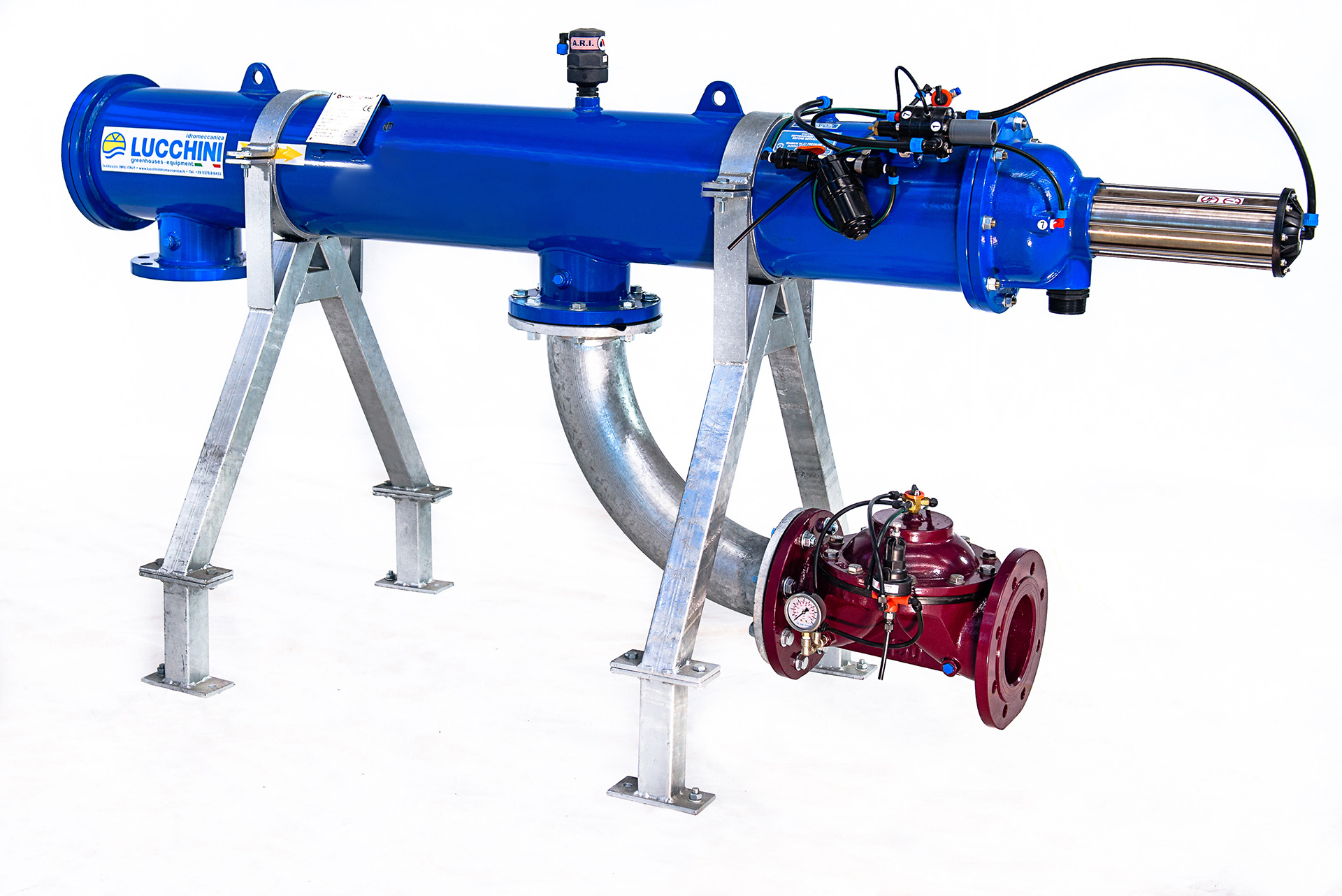

The floating system is based on cultivation over the water, which is recirculated and oxygenated to provide the plants with the necessary nutrients. The plants grow in floating polymer plateaus optimized for the agri-food industry. The hydraulic water recirculation, oxygenation and sanitization system prevents the formation of colonies of bacteria that could make the crops ill. Maintaining an ideal temperature of the liquids favors the fast growth of the plant, while the nourishment directly in contact with the root makes the production more compact and strong.

This cultivation method has numerous advantages compared to traditional cultivation:

• Greater productivity: plants grown in water grow faster and produce higher yields than plants grown in soil.

• Better product quality: products grown in water are fresher, healthier and tastier.

• Lower environmental impact: hydroponic cultivation requires less water, fertilizers and pesticides than traditional cultivation.

The system designed and built by Idromeccanica Lucchini is the result of collaboration between the company and the customer. Constantly listening to production needs and collaborating with the consortium's agronomists has allowed us to operate in the perfect direction to satisfy all the customer's design needs.

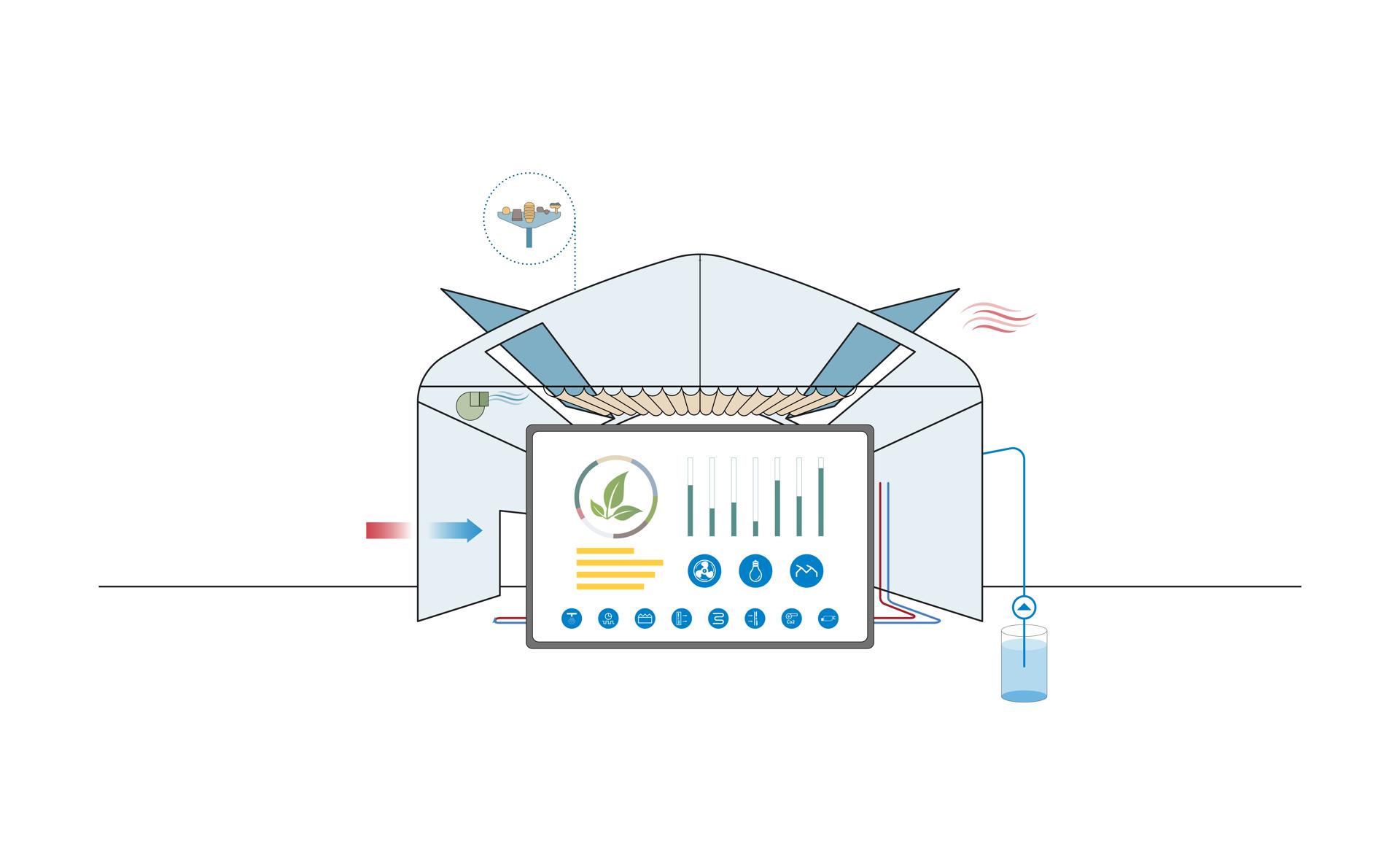

Automation and conditioning

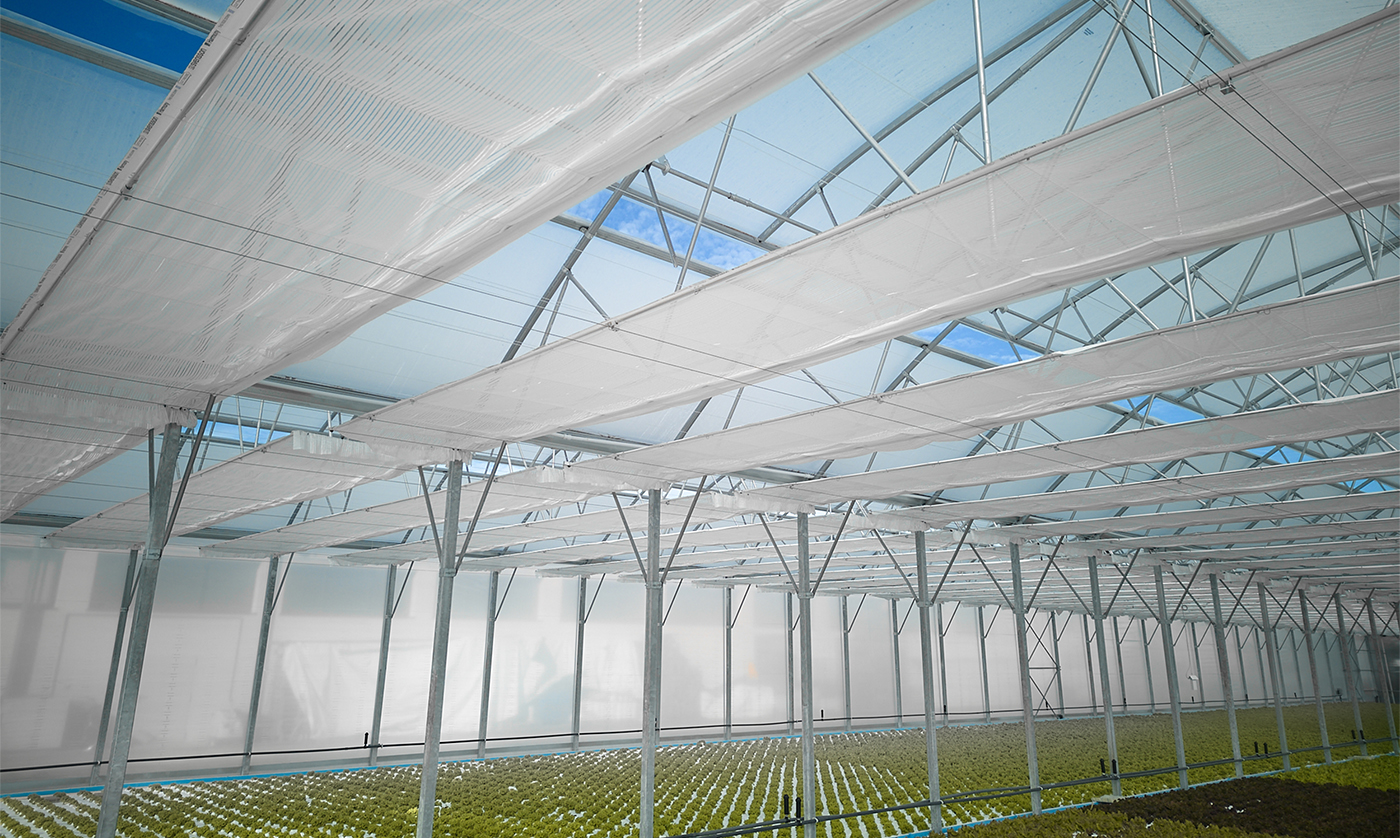

The plant is equipped with an automated control system that allows cultivation parameters such as temperature, humidity and water composition to be monitored and managed remotely. The regulation of the insolation is obtained with automatic screens with light filter and the insulation has been designed to reduce energy costs and create an ideal climate for the plants, also through the automatic management of passive ventilation. Given these characteristics, the project fits perfectly within the parameters of Industry 4.0, thanks also to remote management with tracking of data useful for creating cultivation protocols and calculating production costs.

The design challenges

The project presented the need to guarantee the solidity of the system even in the absence of reinforced concrete building works. The recent European regulations for the protection of the soil and the environment, in fact, do not provide for the installation of the greenhouse through intrusive concrete foundations. To overcome this challenge, Lucchini used geotechnical screws to secure the greenhouse to the ground. The composition and installation of the screws was calculated so as to resist the wind pressure and snow load expected for that specific geographical area. Furthermore, the reduction of civil works helps to save on construction costs.

The frame becomes removable and does not impact the territory, improving the environmental sustainability of the greenhouse. This detail represents a novelty that will increasingly become a paradigm in the future.

The system installed by Idromeccanica Lucchini for the Emilia-Romagna consortium represents an example of how hydroponic technology can be used to produce high-quality horticultural products in a sustainable way. This project could be replicated in other Italian regions and around the world, helping to improve food security and reduce the environmental impact of agriculture.